Description

Elevate Your Operations with the Toughcut TCCWC-1500W: Cutting, Welding, and Cleaning in One Powerful Machine

Product Overview

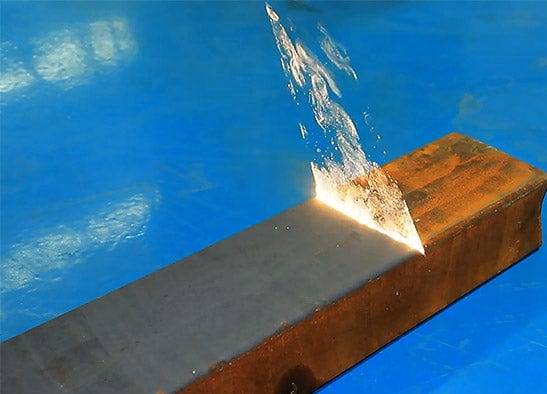

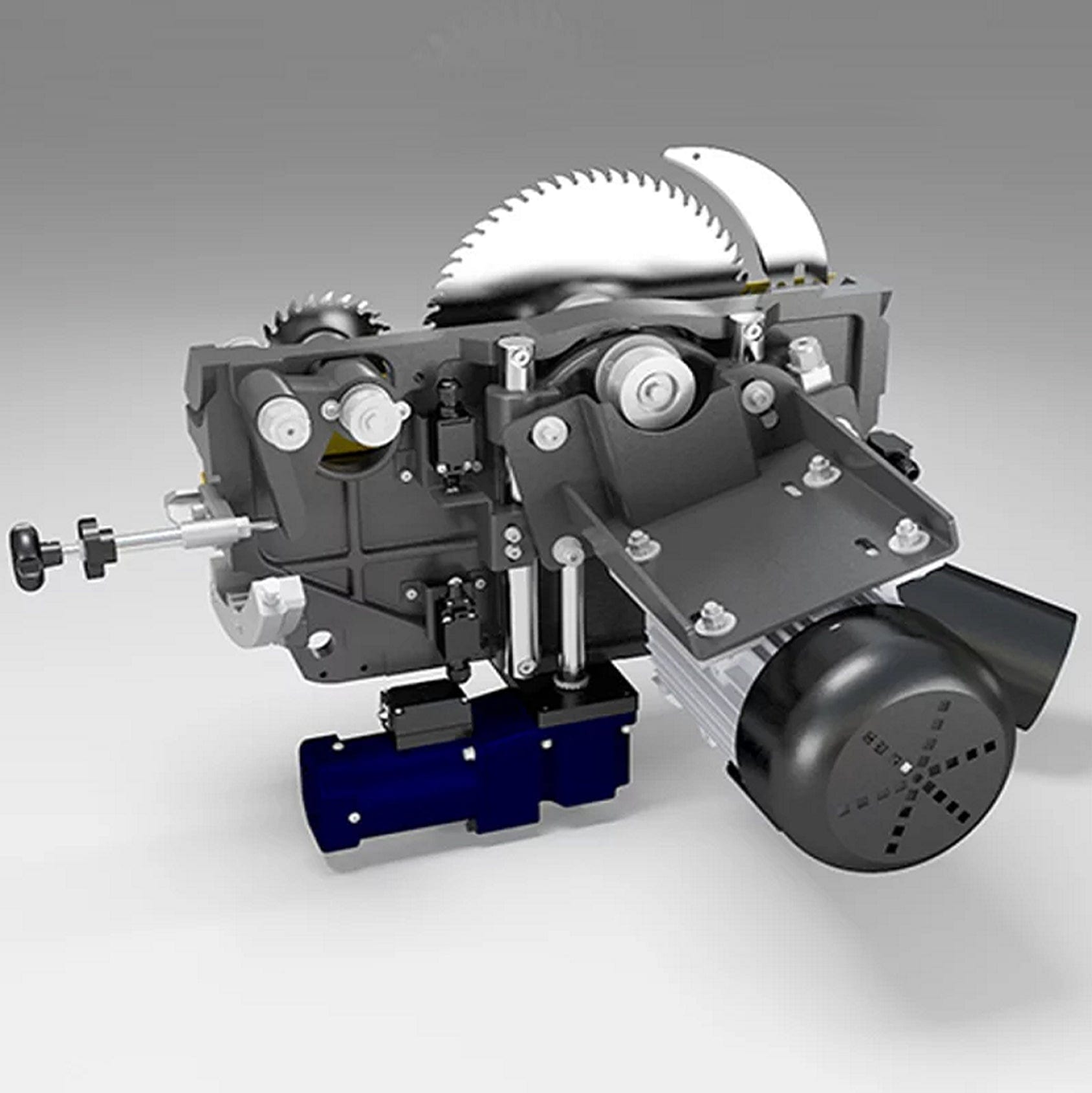

Introducing the Toughcut AKWH-1500W 3-in-1 Fiber Laser Machine, the ultimate solution for modern manufacturing needs. This versatile machine combines laser cutting, welding, and cleaning capabilities in one compact unit, providing unmatched flexibility and efficiency for a wide range of industrial applications.

Key Features

- Triple Functionality: Seamlessly switch between laser cutting, welding, and cleaning functions to meet diverse operational needs. Equipped with Ruida system, the conversion of each function is convenient and simple.

- High-Power Fiber Laser: Equipped with a robust 1500W fiber laser source (with custom made to order options to increase to 2000W or 3000W), delivering exceptional performance across all three functions.

- Precision and Accuracy: Advanced laser technology ensures fine cuts, strong welds, and thorough cleaning, all with minimal material waste.

- User-Friendly Interface: Intuitive control panel with an easy-to-use interface for quick setup and operation.

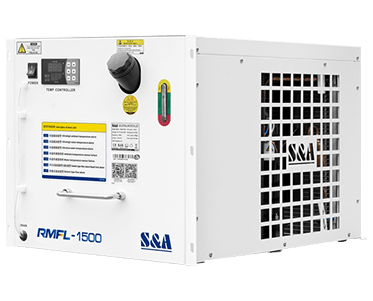

- Efficient Cooling System: Integrated cooling system maintains optimal performance and prolongs the machine's lifespan.

- Robust Build: Constructed with high-quality materials for durability and long-lasting performance in industrial environments.

- Automated Features: Includes automated systems to streamline operations and reduce manual labour.

- Portable design: The body has a compact and ergonomic design. The bottom of the fiber welder cleaner has wheels, which can be moved freely and can be taken to any workplace where welding and cleaning are required.

- Easy to operate: Fiber welder cleaning machine is easy to operate, and novice welders can master cleaning and welding operations with only a few hours of training. Reduce labour costs while improving quality, consistency, and productivity.

- Economical: The fiber welding cleaning machine is an economical and intelligent innovative product. For different application scenarios, the corresponding nozzle nozzles can be easily and quickly replaced, making tedious processing simple and efficient.

Technical Specifications

- Laser Power: 1500W

- Cutting Speed: 0-120mm/sec

- Welding Speed: Adjustable based on material and thickness

- Welding Gap Requirements: ≤0.5mm

-

Welding Depth: 0.1 - 4mm

- Cleaning Efficiency: High-efficiency cleaning with adjustable parameters at 12m2/Hr

- Repeat Precision: ±0.01mm

- Scanning Width: 10-80mm

- Pulse Frequency: 30-80KHz

- Laser Wavelength: 1080nM

- Supported Materials: Stainless steel, carbon steel, aluminium, brass, copper, and more

- Cooling System: Water-cooled

-

Control System: CNC control panel with touchscreen interface

- Expected Focal Distance: 160mm

-

Cable Length: 10m

Applications

- Automotive Manufacturing: Precision cutting, strong welding, and effective cleaning of metal components.

- Aerospace Engineering: High-precision cutting and welding for complex aerospace parts, with efficient cleaning.

- Metal Fabrication: Versatile cutting, welding, and cleaning for various fabrication needs.

- Electronics: Fine cutting and welding for electronic components, with precise cleaning.

- Medical Devices: Precision cutting, welding, and cleaning for medical equipment and instruments.

Why Choose Toughcut AKWH-1500W?

- Unmatched Versatility: Combines cutting, welding, and cleaning in one machine, offering flexibility for various tasks.

- High Efficiency: Speed up your production process with high cutting and welding speeds, and efficient cleaning.

- Precision and Quality: Achieve superior cut quality, strong welds, and thorough cleaning with minimal waste.

- Durability: Built to withstand rigorous industrial use, ensuring long-term reliability.

Equipment Features

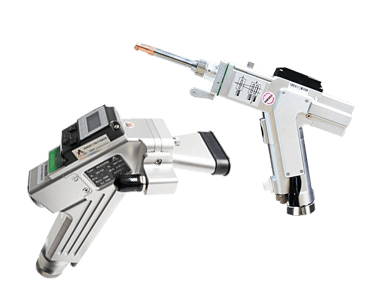

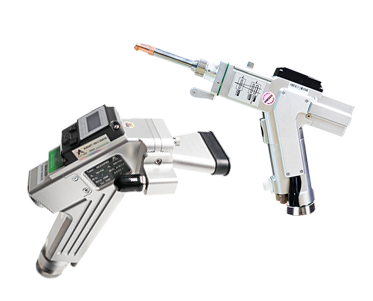

Au3tech Laser Cleaning and Welding Gun

The intelligent cleaning welding gun with temperature monitoring can monitor the protective lens and give early warning of damage. It is easy to use, flexible in processing, small in size, easy to carry, and low in operation and maintenance costs.

The lasers have higher electro-optical conversion efficiency, higher and more stable optical quality. Low error rate, low power consumption, maintenance-free and compact.

The system is easy to operate and can display real-time input and output IO status, alarm information and motion status.

The process parameter library is stored in the laser cleaning and welding machine. Each mode corresponds to different parameter settings. After saving, you can directly select the corresponding mode next time without setting the parameters again.

The built-in chiller design can avoid the shackles of wires to fit more sites and has good dustproof effects. A powerful and stable water cooling system will ensure the perfect working of the fiber laser source.

Contact Us

For more information or to request a quote, contact us. Upgrade your operational capabilities with the Toughcut AKWH-1500W 3-in-1 Fiber Laser Machine today!

YouTube Videos

Additional Information

What's Included

Optional Accessories

Spare Parts

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

hidden

You may also like

Shop All Sale

Summer Essentials

Shop Woodfast

Shop Woodworking