Description

WHAT IS A SHOP MASTER?

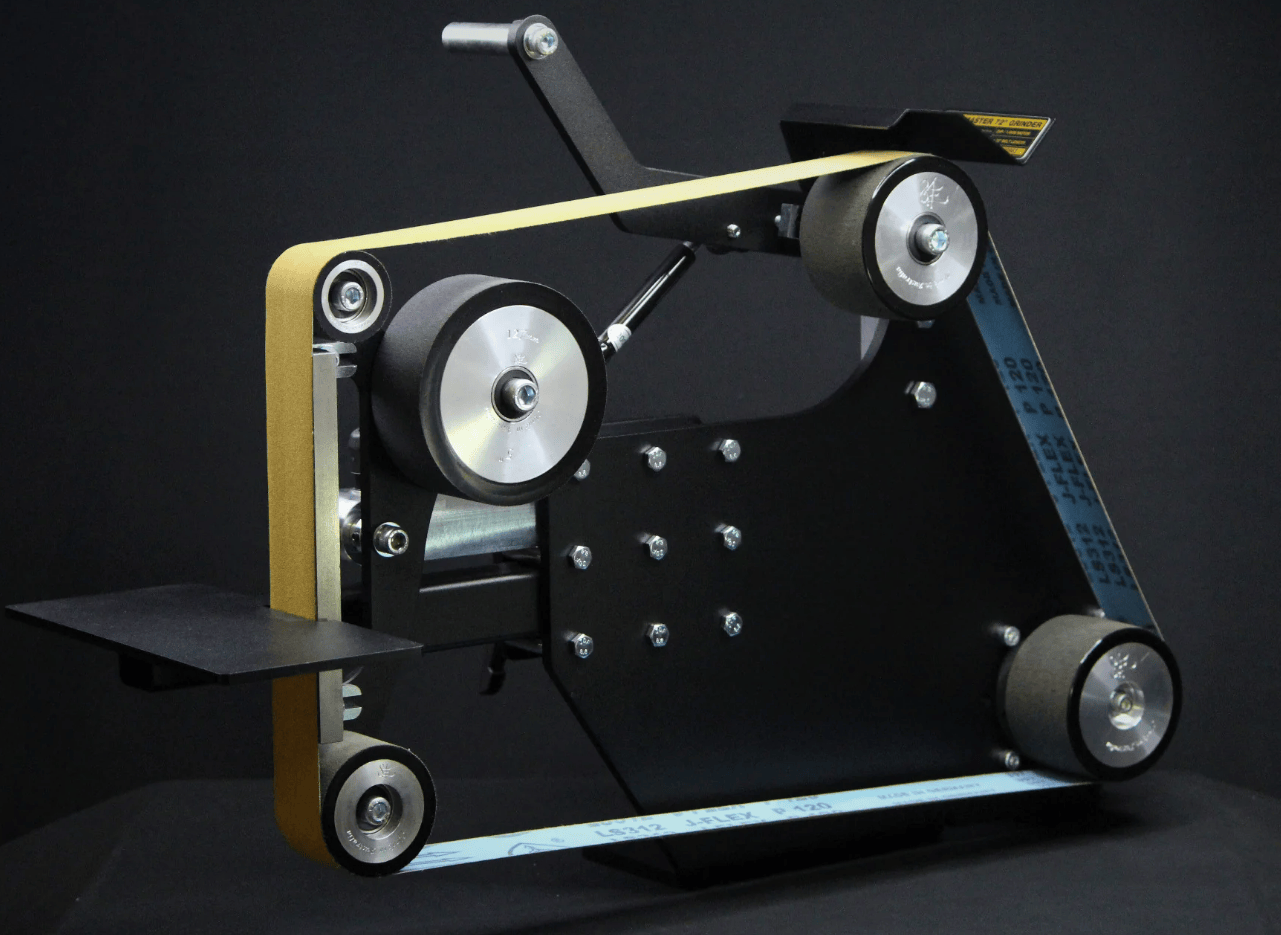

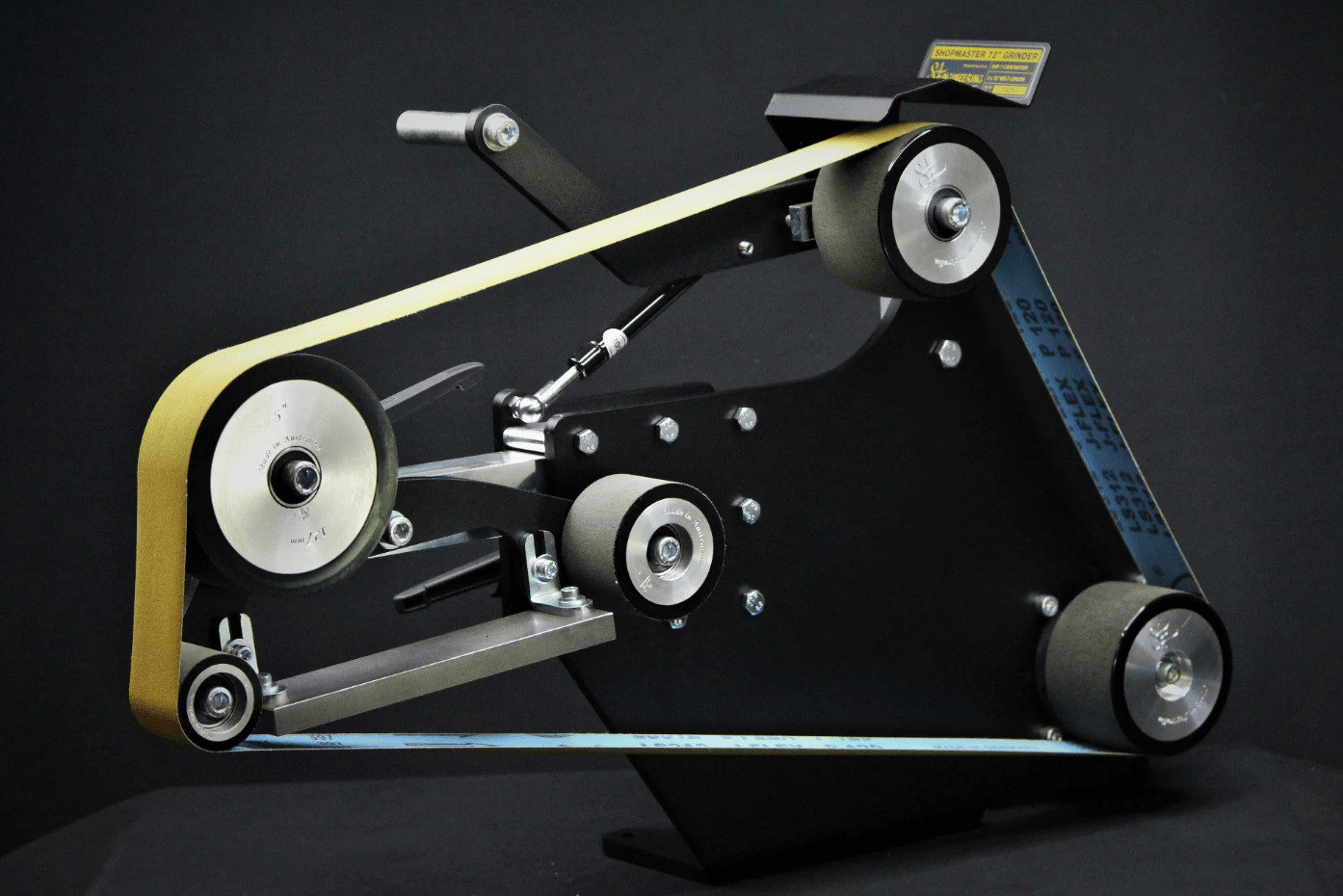

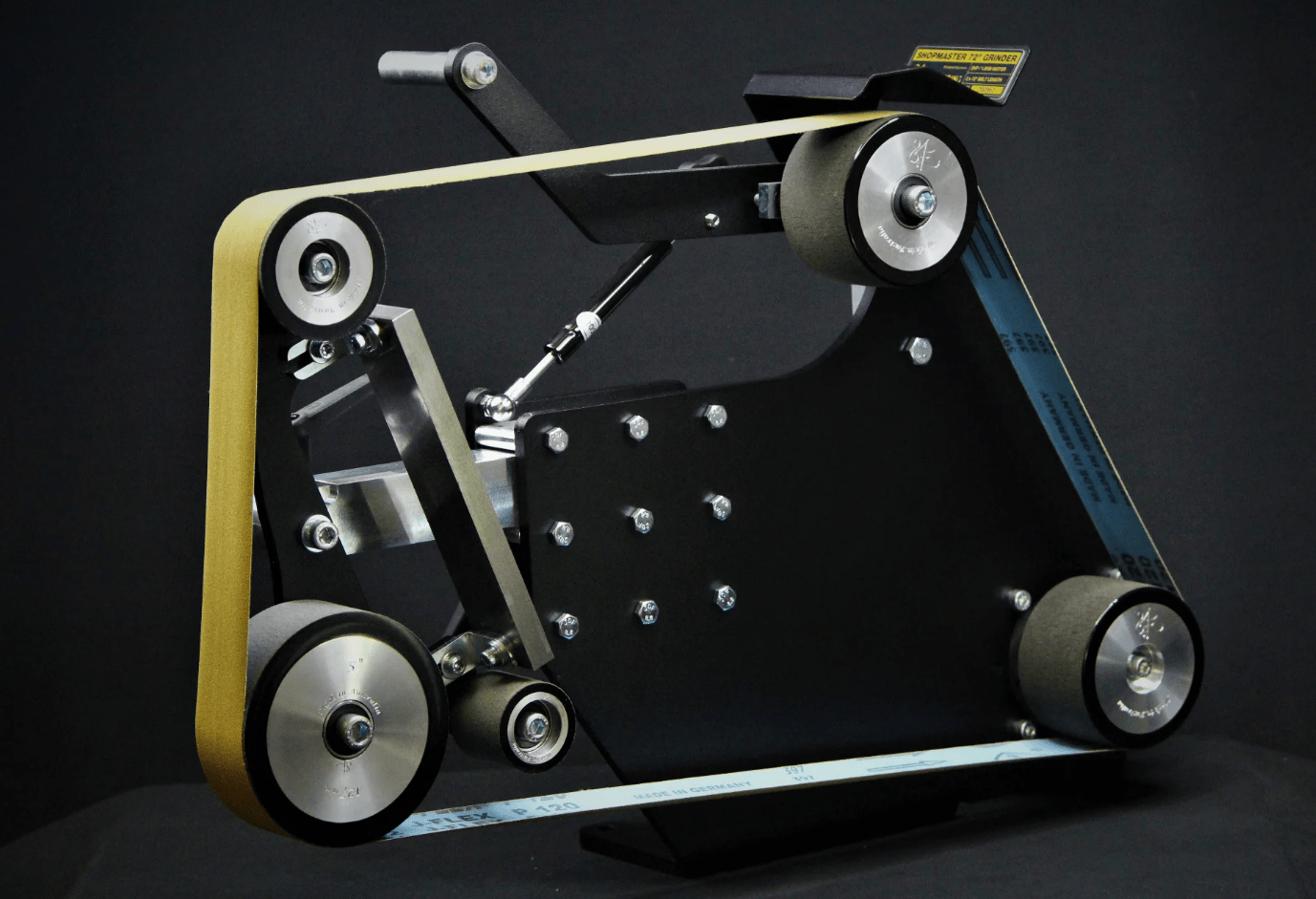

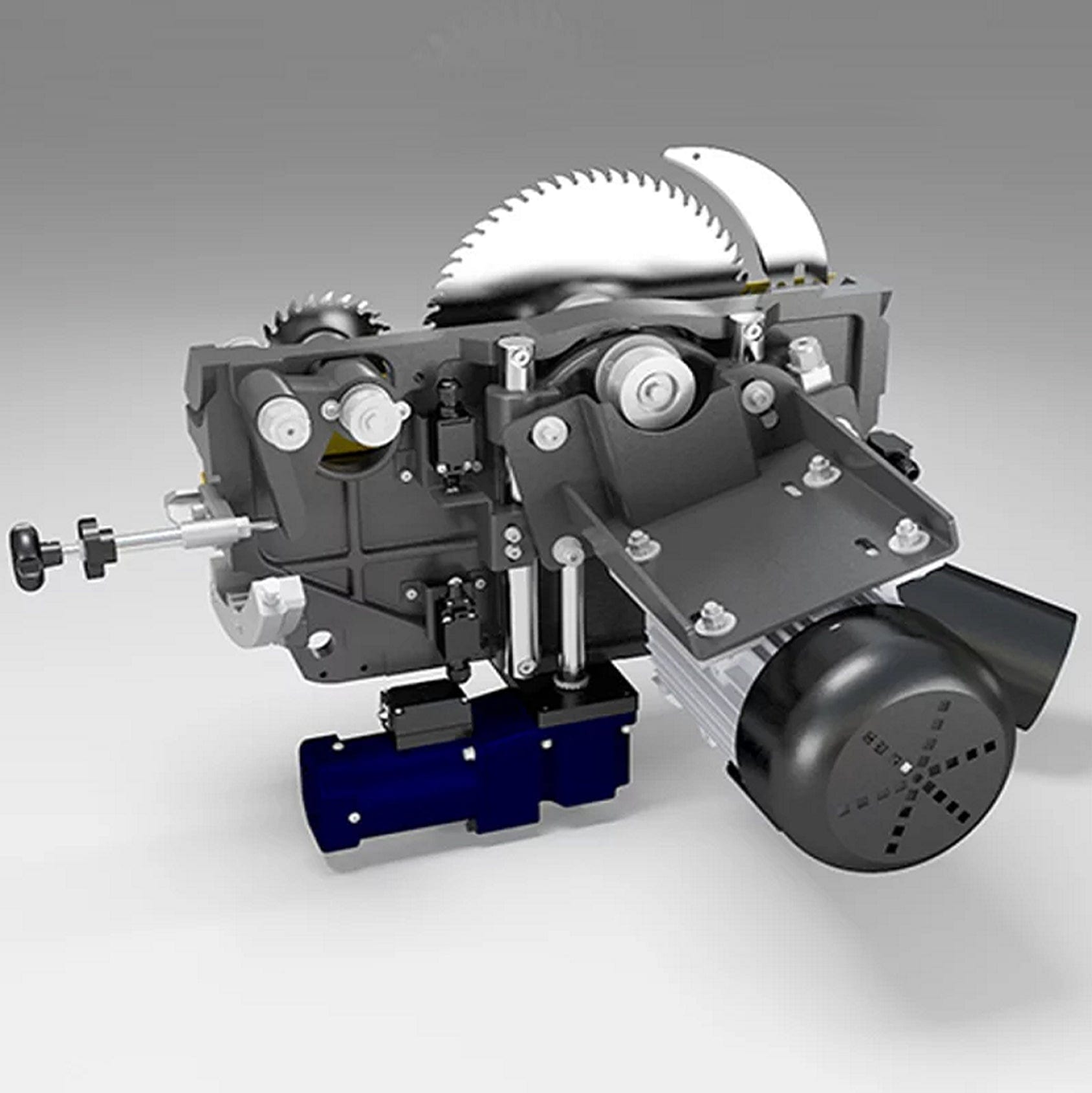

The Shop Master 2x72” Belt Grinder Linisher is a premium machine for serious fabricators, metal workers and knife makers wishing to get into the 2x72” belt size.

The sleek, single-piece folded body is laser cut from 10mm plate steel and makes for an extremely rigid yet uncomplicated chassis. All body components simply bolt together using basic hand tools, making servicing and assembly a breeze.

VERSATILE

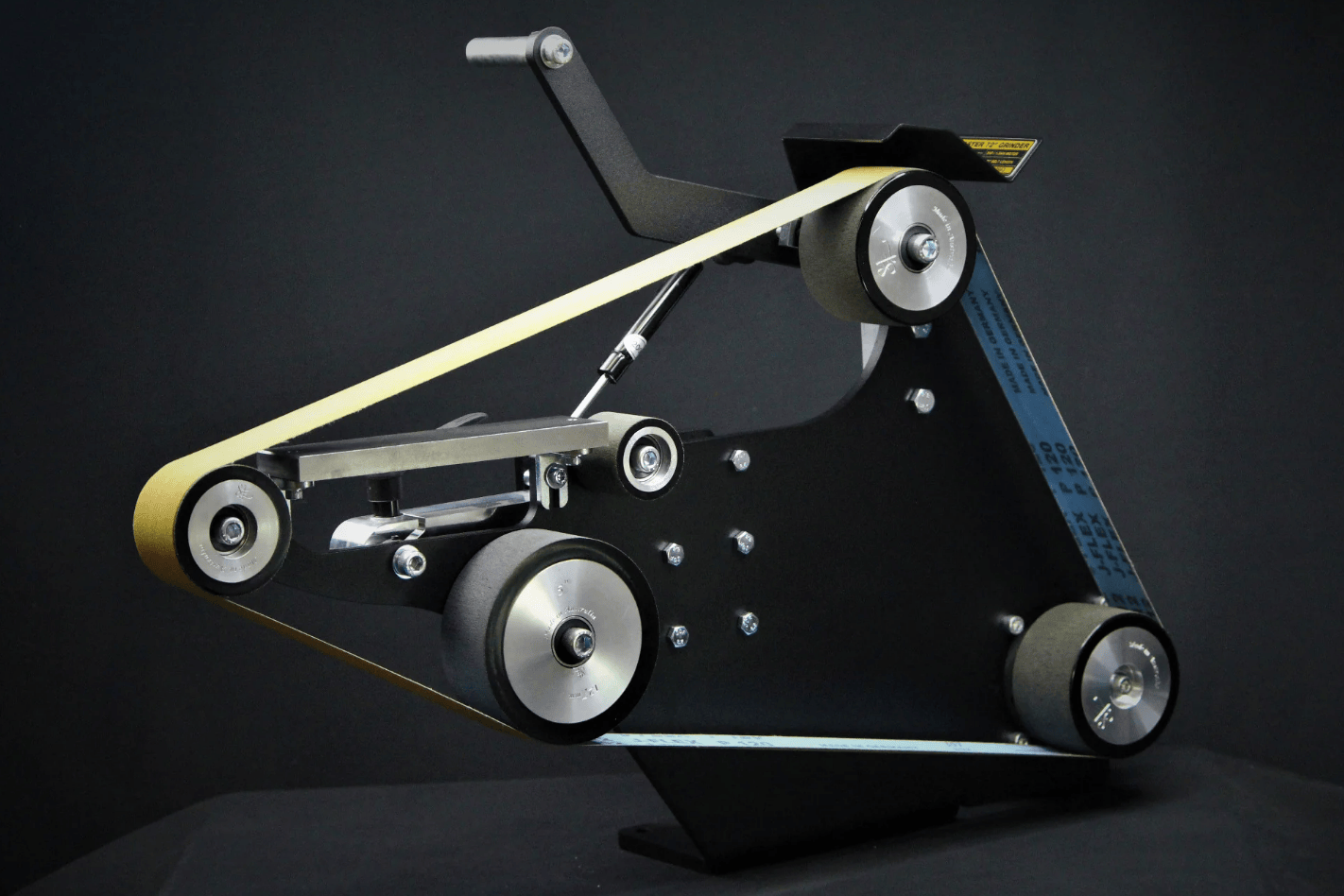

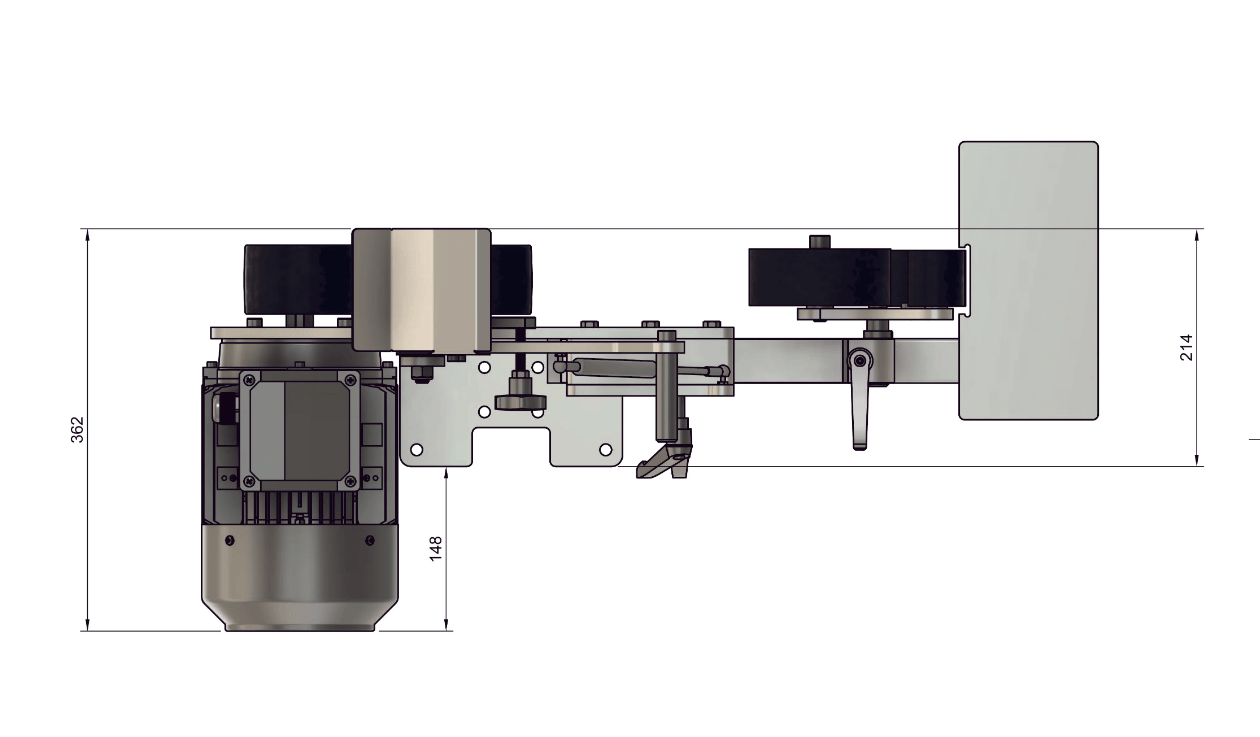

The Shop Master 2x72” belt grinder linisher is one of the most versatile and easy to use machines on the market, equipped with a fixed steel work rest and a 6-in-1 rotating platen. Simply loosen the locking handle on the tooling arm and rotate the platen to change between the 215mm steel platen, a 2”, 3” & 5” rubberised contact wheel, or two different slack belt options. This design also offers ample clearance on either side of the platen making it easier to grind corners and edges on awkward work pieces.

If you require more versatility, our full range of accessories are compatible with the Shop Master 72" belt grinder and can be easily swapped out via the quick-change tooling arm slots.

POWERFUL

The Shop Master grinder linisher will plug into any standard 240v 10a power socket. The included variable frequency drive (VFD) / speed controller converts power to a 3-phase signal, driving the 1.5kw (2hp) motor. This setup allows you to dial in the belt speed anywhere from 0 – 4800 fpm and provides maximum motor torque even at low RPM. The VFD will automatically ramp up power when under load to maintain belt speed.

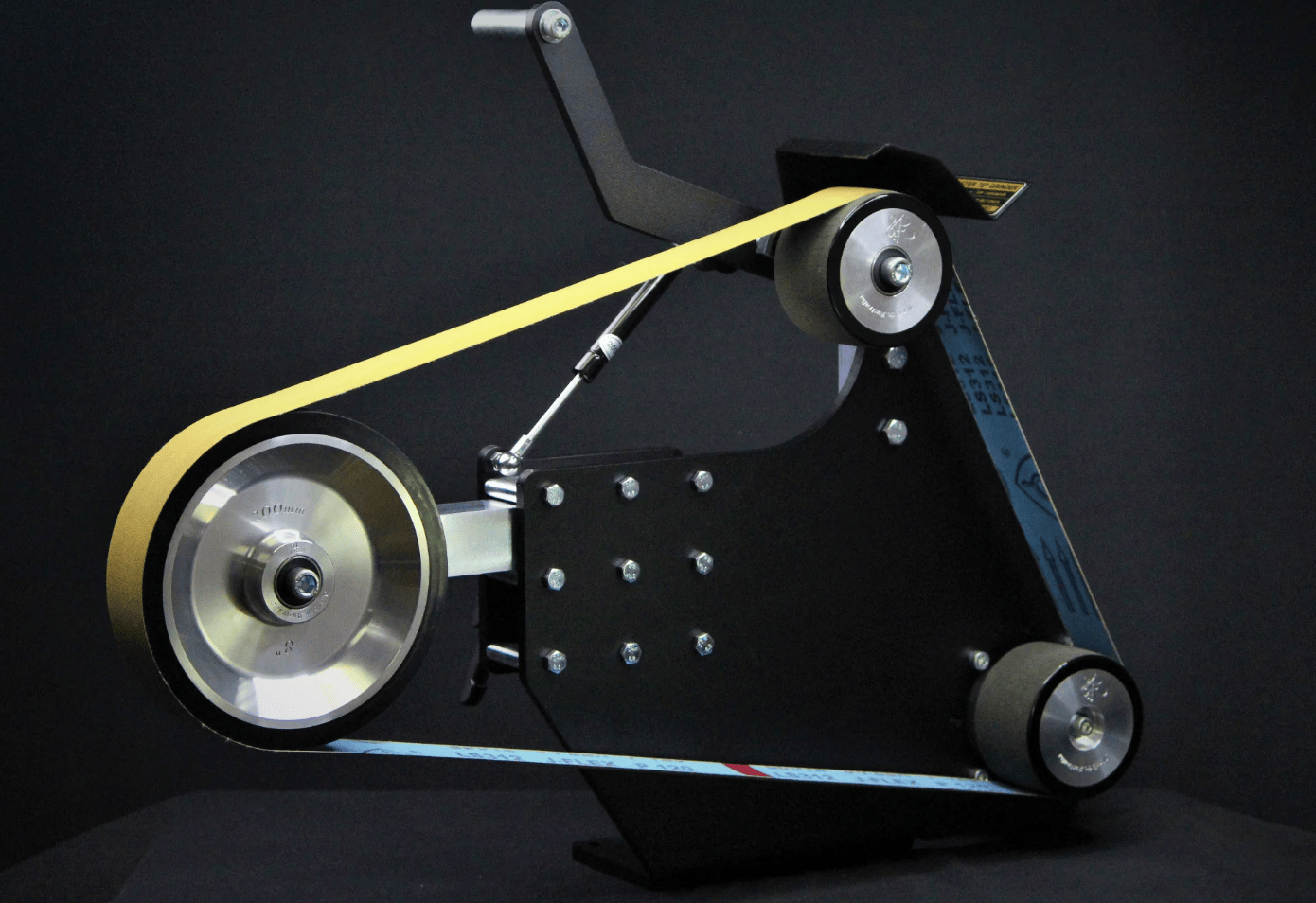

URETHANE WHEELS

All wheels on the Shop Master belt grinder linisher are precision CNC machined from 6061 billet aluminum and coated in our newly formulated abrasion-resistant urethane rubber. Not only does this provide excellent drive wheel traction (the belt will never slip, regardless of how much pressure you apply), but makes for quieter operation and a superior grinding experience. The rubberised wheels even out belt discrepancies meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit belts / abrasives.

STABLE TRACKING

The Shop Master’s flat-plane tracking mechanism offers increased tracking stability and ease of adjustment over many other options available on the market. The tracking is set-and-forget; just dial in tracking with the twist of a knob and it will remain true, even under heavy belt load. The flat-plane tracking also allows for minimal crown/curvature of the tracking wheel, so your j-flex and other lighter abrasives / belts won't deform over time.

AUTOMATIC TENSIONING

The gas strut tensioning system ensures a consistent belt tension regardless of tooling setup. The tension arm is designed to lock down when the arm is in its lowest position, allowing for effortless belt and tool changes - you can even do it single handed!

ASSEMBLY?

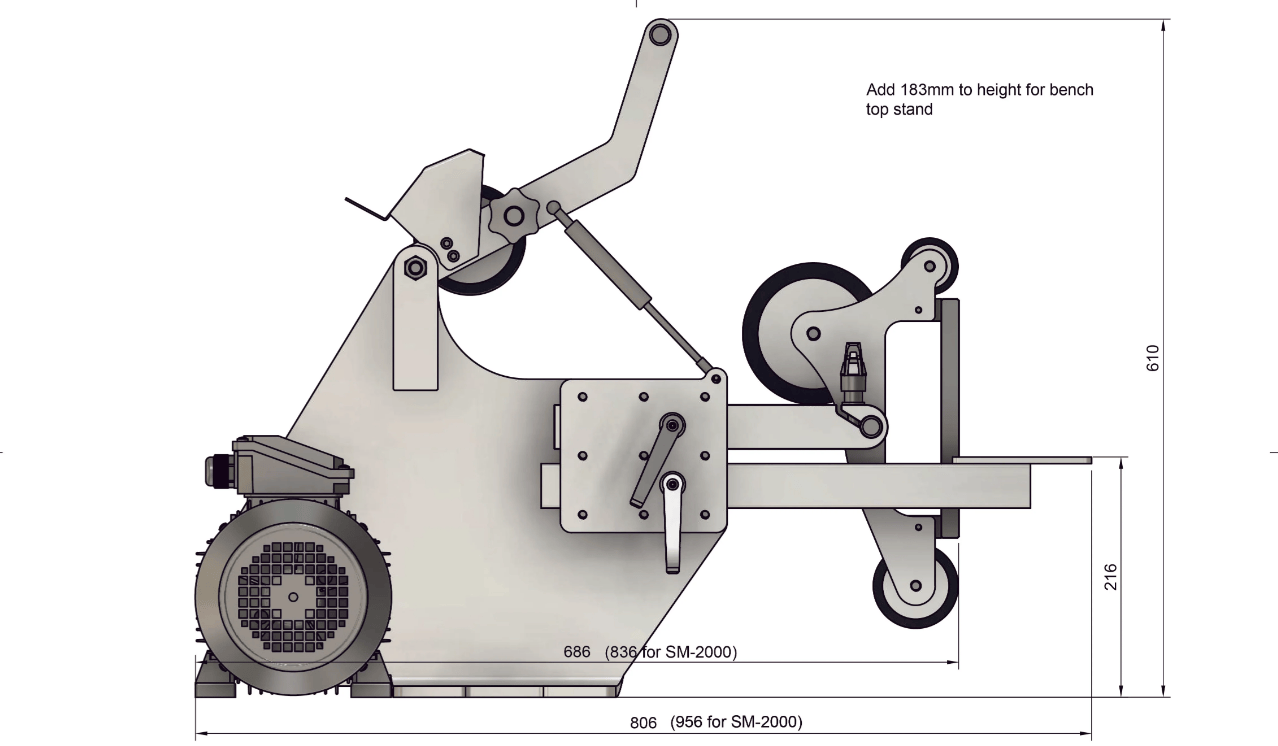

Due to the weight of the Shop Master, the we have broken the grinder down into 2 cartons. In one carton is a semi-assembled, powder coated body, assembled platen and drive wheel. In another box is a pre-wired motor and VFD. Simply bolt motor to the body, install the drive wheel and your grinder is ready to go

Product Specifications

- 2 × 72” belt length

- Pre-wired 2 hp 1.5 kW motor and VFD

- 8″ / 210mm platen - Rotating platen

- 2”,3” and 5" contact wheels

- Rubber coated wheels for smooth performance and great belt traction

- Flat plane belt tracking for accurate belt alignment

- 2 tool arm slots

- Fixed work rest

- Protective spark guard

Additional Information

What's Included

Optional Accessories

Spare Parts

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

hidden

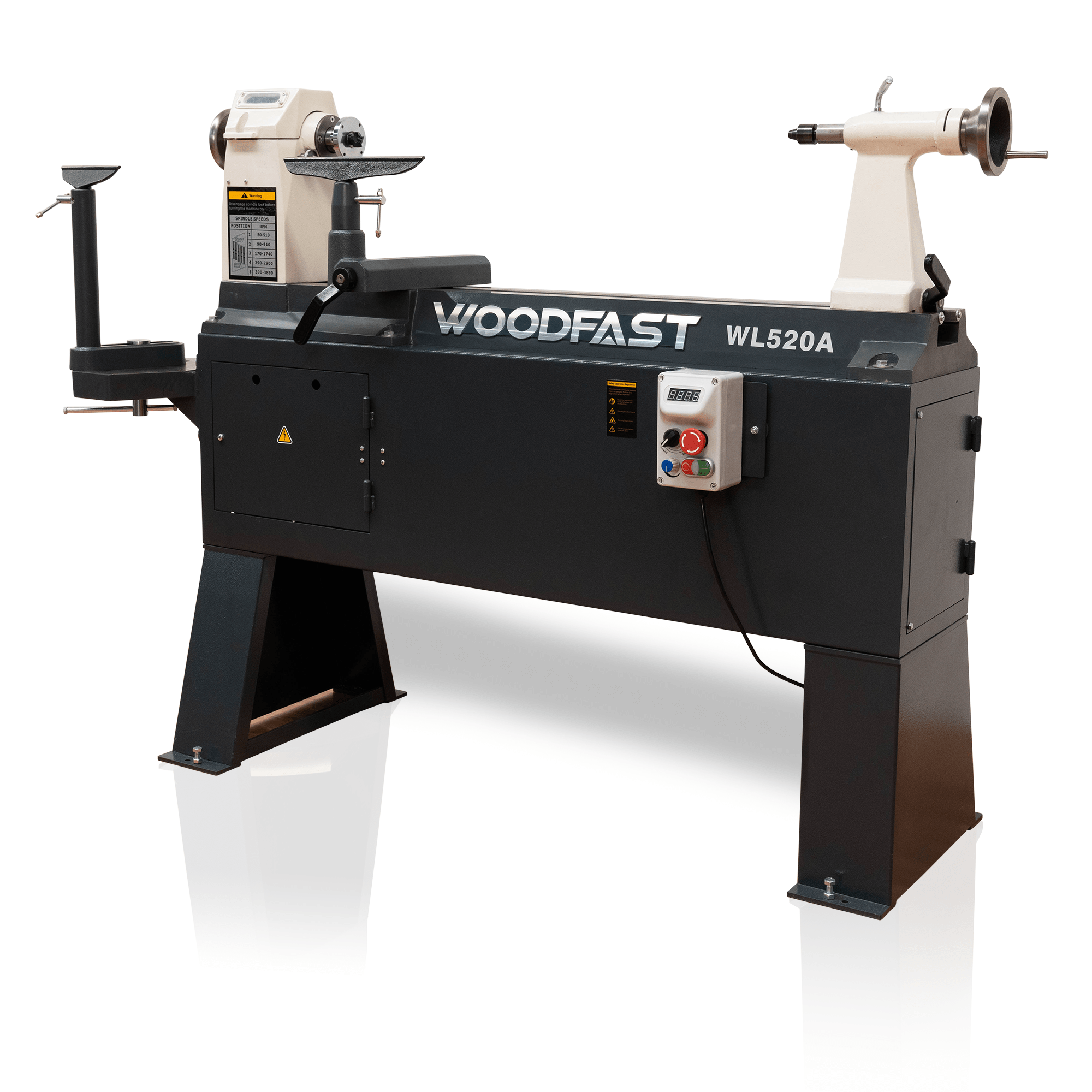

You may also like

Shop All Sale

Summer Essentials

Shop Woodfast

Shop Woodworking