Description

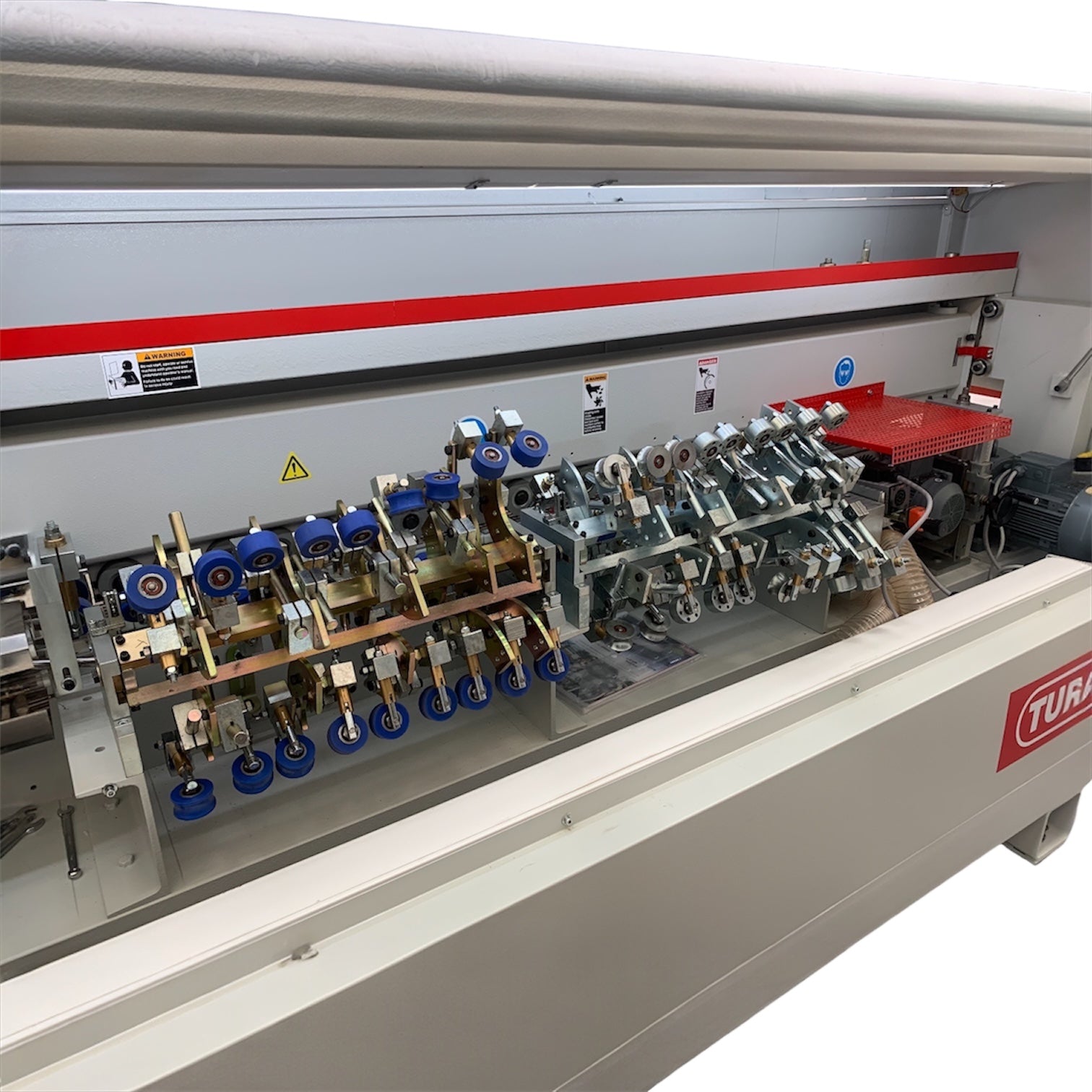

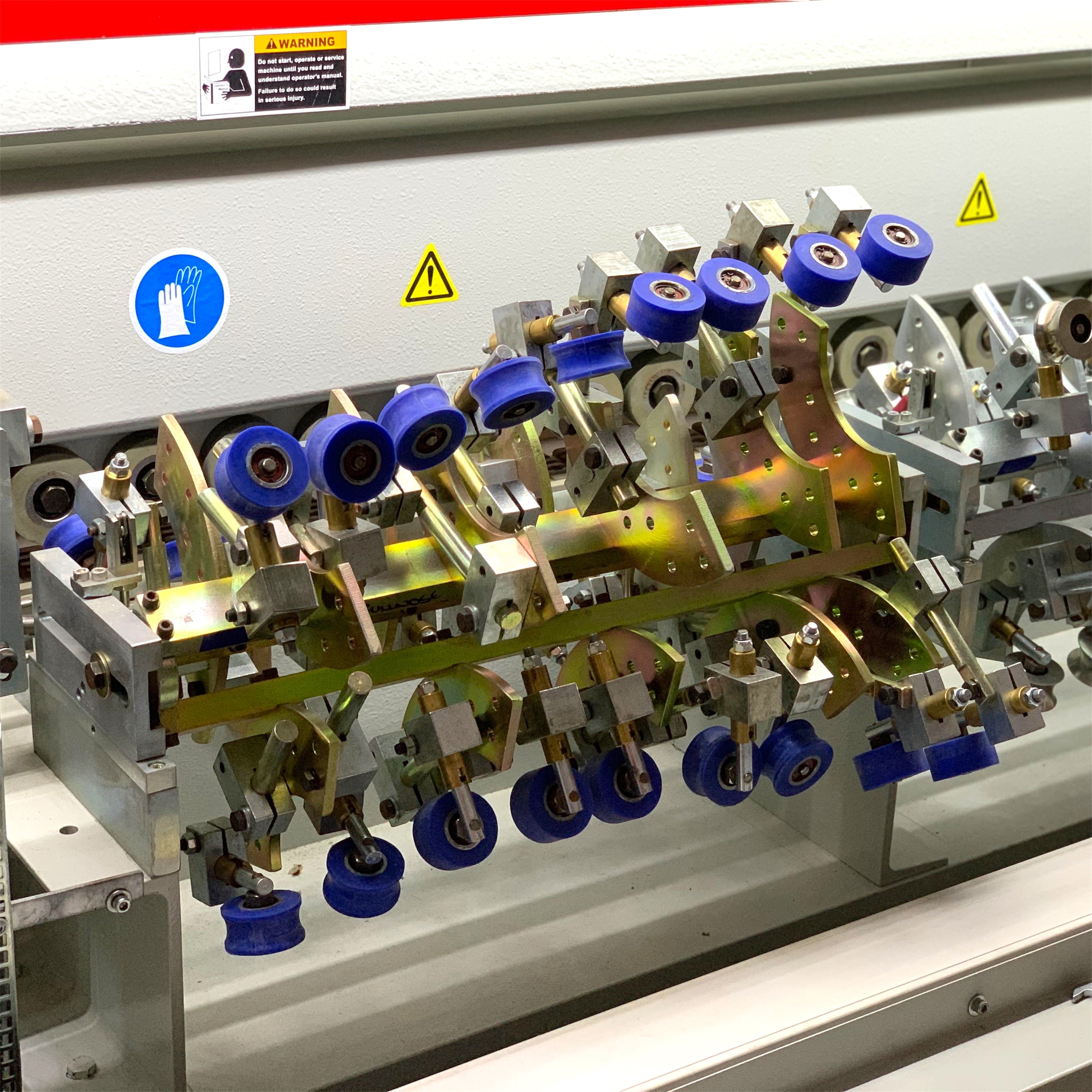

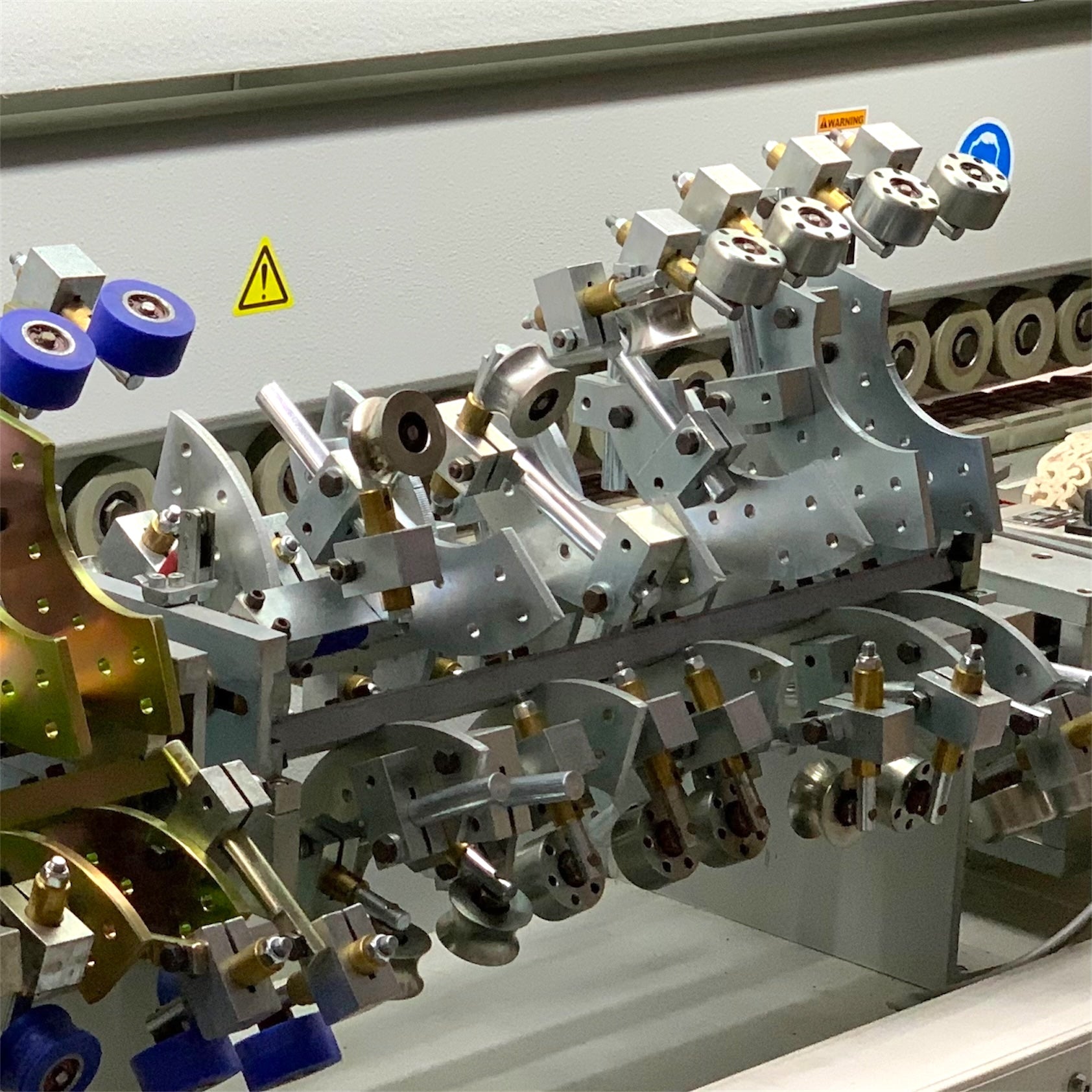

This Machine Curves and Softens the Laminate with Heating Lamps and Applies onto Profiled Edges utilising unique Feed Profile Rollers. The T-PF280 is extremely functional and equipped with Top-Bottom Infrared Medium Wave Heating Lamps, Profile Cartridge (which can be set for 3 different profiles), Cooling Rollers, End Milling Unit and Speed Adjustment.

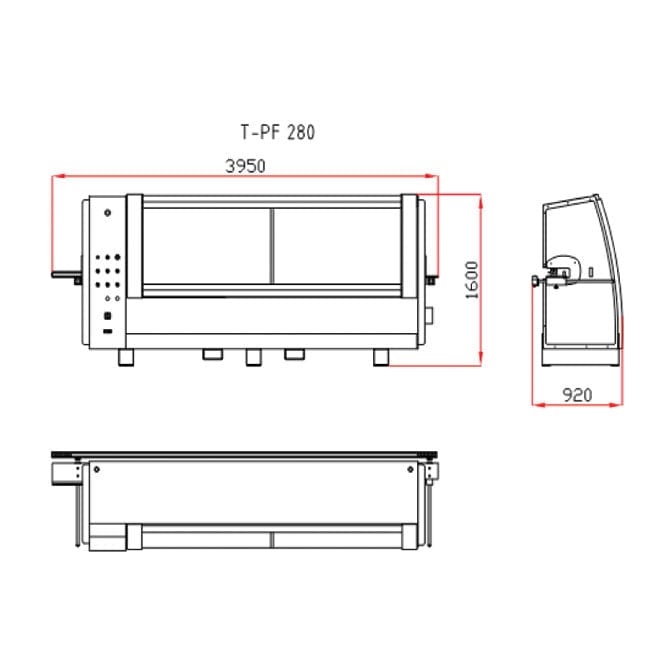

Specification

- Laminate Thickness: 0,4 - 1 mm

- Laminate Height: 70 mm

- Speed: 12 m/min.

- Total Electrical Power: 7,6 kW

- Working Height: 870 mm

- Machine Width: 920 mm

- Machine Length: 4000 mm

- Machine Height: 1600 mm

- Machine Weight: 1600 kg

- Trimmer Power: 0,37 kW 12000 Rpm

- Dust extraction Outlet: 150mm

INFRARED (MEDIUM WAVE) TOP & BOTTOM HEATERS UNIT

• They are 1750Watt/each, gold bladed glass tubes and imported from Germany.

• The big advantage with this heaters; the length of the panel does not matter at all,

customer can feed 4-5 meters table top and the temperature will remain same always as

on the beginning.

• Just 5-10 minutes to heat the elements is required at the beginning

TRIMMING UNIT

High Frequency Italian Motor with 12000 rpm (same like the edgebanding trimming motors)

Placed on the bottom; in order to clean the amount in excess (overhangs) of the laminate.

Only to use for half turn (90 degree) profiles, when customers using full turn (180degree) this motor must not switched on and

move down little bit.

Sample profiles when you can use the trimming motors

GROOVING SAW UNIT

Especially for the kitchen-tops It is a very necessary unit, as you know, with the help of grooving unit most of the users are filling this

grooves with silicon, hot-melt or something else against to water drops.

Placed on the bottom like trimming unit.

Please note : Tightness of radius is all dependent on laminate type, thickness, age and colour. Minimum radius is generally 6mm with the correct squareformable laminate. 8mm is for most laminates.

Machine is a contact glue machine only. Recommend Tac adhesive glue for best results on square form.

Additional Information

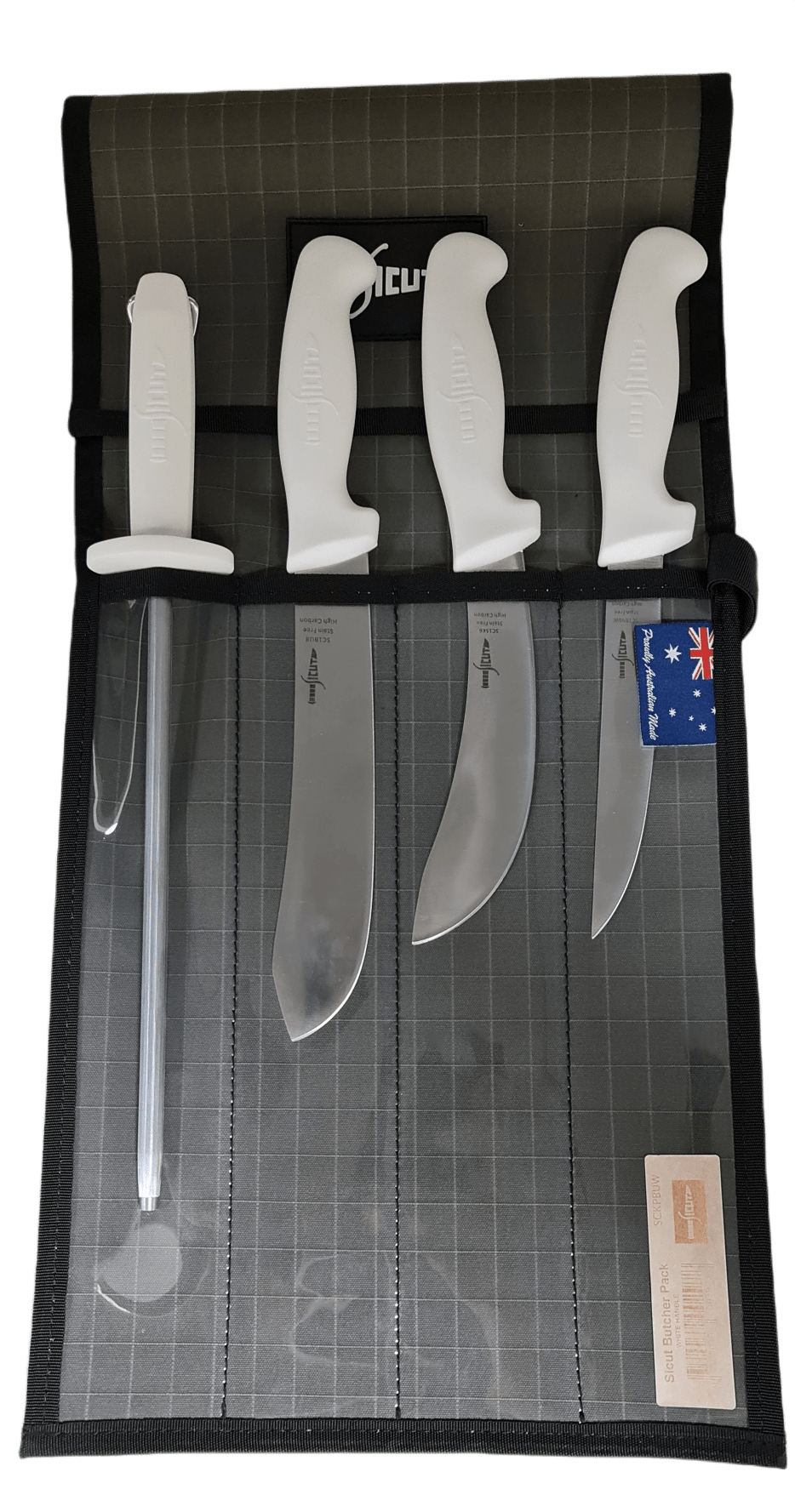

What's Included

Optional Accessories

Featured collection