Description

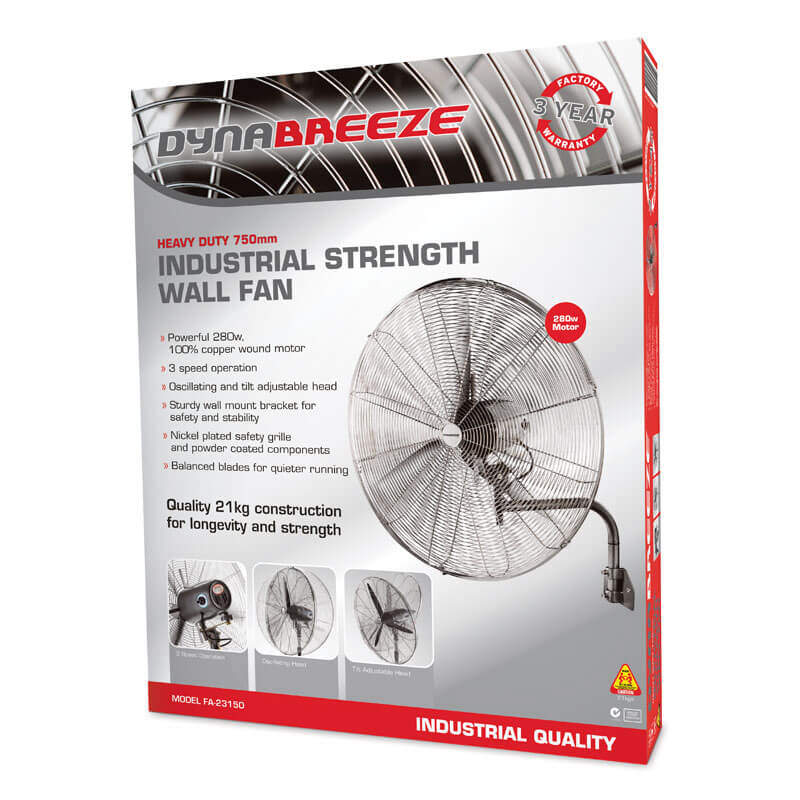

*Scratch + Dent Stock as its the last of this discontinued stock line - the packaging may be old, shop soiled, display use*

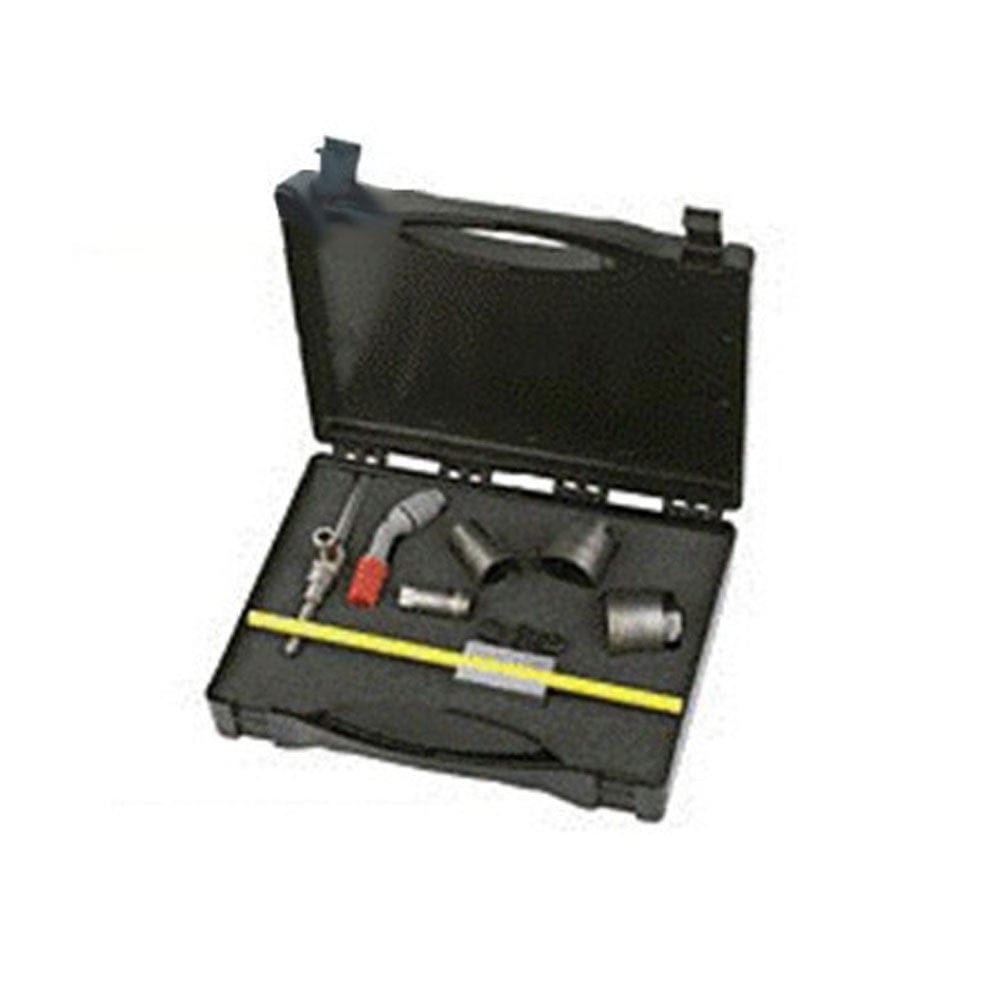

A full range of handy, job specific starter sets with everything needed to complete the drilling of porcelain tile. The range enables the user to buy the necessary components to drill a specific large diameter hole together in one set.

All starter sets supplied with water feed adaptor, water feed tube and nozzle, water feed clamp, PTC Carbide 8.0mm pilot drill, 8.0mm professional masonry drill and PTC Diamond crown diameter as shown above. Size in brackets indicates crown size.

Features:-

The fastest, simplest solution for small diameter holes - simply push, cool and drill- Purpose Designed Tip Tolerances Holes are produced slightly oversized in the tile. Allows fixings to be secured and expanded in the material behind the tile, not on the tile edge itself, reducing the risk of cracked tiles

- P100 Grade Tungsten Carbide Tip P100 grade tungsten carbide tip provides durability when drilling in the hardest of tile materials

- Unique Head Geometry Unique geometry of the cutting head allows the drill bit to rapidly cut through the materials without burning or glazing the tile

- Diamond Ground 'Drill Tip' 4 unique grinds to the top of the drill tip mean the drill 'bites' into the tile providing a 'point & push' start up with no leaning in required and no wander on the tile. Accurate holes are produced exactly where required

- Anchor and fastener holes for small size plugs and anchors from 5 to 10mm

- 8mm pilot holes for PTC diamond crowns from 13 to 58mm

- Plaster-backed wall tiles

- Ceramic

- Natural slate

- Travertine

- Marble

- Granite

- Quarry tiles

- Porcelain

- Insert the required PTC bit into the power tool and ensure the bit is tightly secured in the chuck. Use the manufacturers recommended lubricant in the case of SDS+ machines.

- Position the tip of the drill bit on the tile and, before drilling commences, push the tool onto the tile. A small 'cracking' sound should be heard, which is the PTC bit locating itself in the tile.

- Ensure that the drill bit is perpendicular to the work surface. Failure to drill perpendicular to the tile will result in slower drilling speeds and premature wearing of the drill bit.

- Ensure a continuous flow of water to the cutting tip during the drilling operation. This is imperative to the successful operation of the PTC bit. (Refer to water cooling section).

- Enough pressure must be applied to the drill bit to ensure cutting action. A good guide to this is the water will be disclosed by the tile dust when enough pressure is being applied. Some grades of porcelain require a higher pressure than others. The pressure applied can be reduced when the point of the tool has penetrated beyond the back surface of the tile.

- The optimum speed range for using PTC carbide products is 700-900 r.p.m. on rotary only. Do not use hammer action.

- When drilling on groutlines or part-drilled holes is unavoidable, ensure drill is running at optimum speed before commencing to drill.

- Once breakthrough of the tile has been achieved, stop drilling. The PTC drill bit should then be changed for a professional masonry or SDS bit.

- When drilling a loose tile, the tile must be supported across its entire area on something perfectly flat that isn't going to damage the cutting edges of the drills e.g. piece of flat wood, mdf, chipboard etc.

- If possible, clamp loose tiles to prevent possible movement on breakthrough. Movement of the tile can cause large diameter drills to 'grab" which could cause personal injury or cracked tiles.

- When PTC carbide bits have reached the end of their life in porcelain, they can still be used to produce holes in softer materials.

- Please ensure that the following safety guidelines are adhered to at all times when using or handling the PTC drill bit

- Wear suitable eye protection at all times during assembley and operation.

- Safety gloves should be worn at all times.

- Ear defenders should be worn whilst drilling.

- Whenever the drill is not in use, ensure that the power is turned off.

- Wear a dust mask whilst drilling.

- Use an RCD device if using an electric power tool.

Additional Information

What's Included

Optional Accessories

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

hidden

You may also like

Shop All Sale

Shop our Catalogue

Summer Essentials

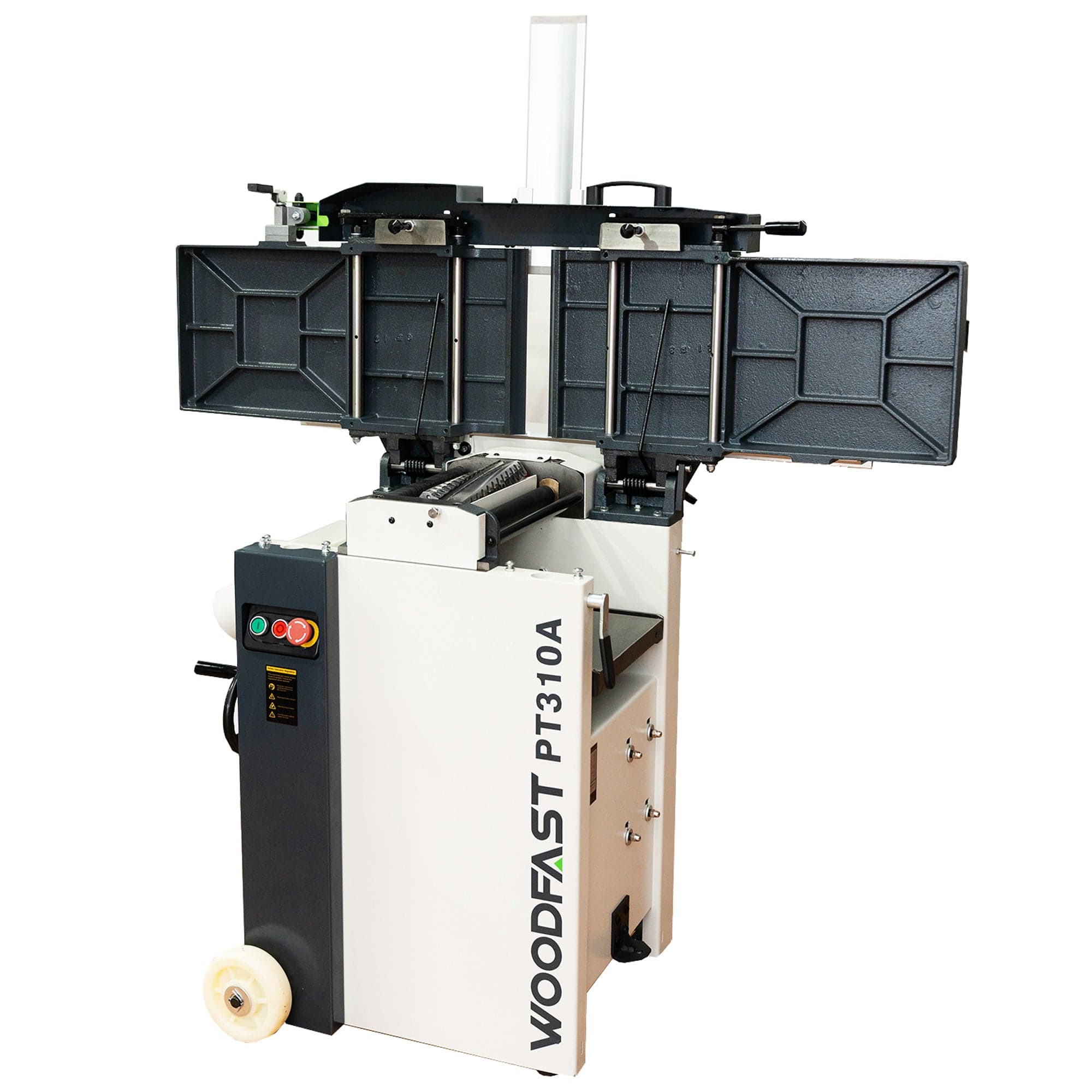

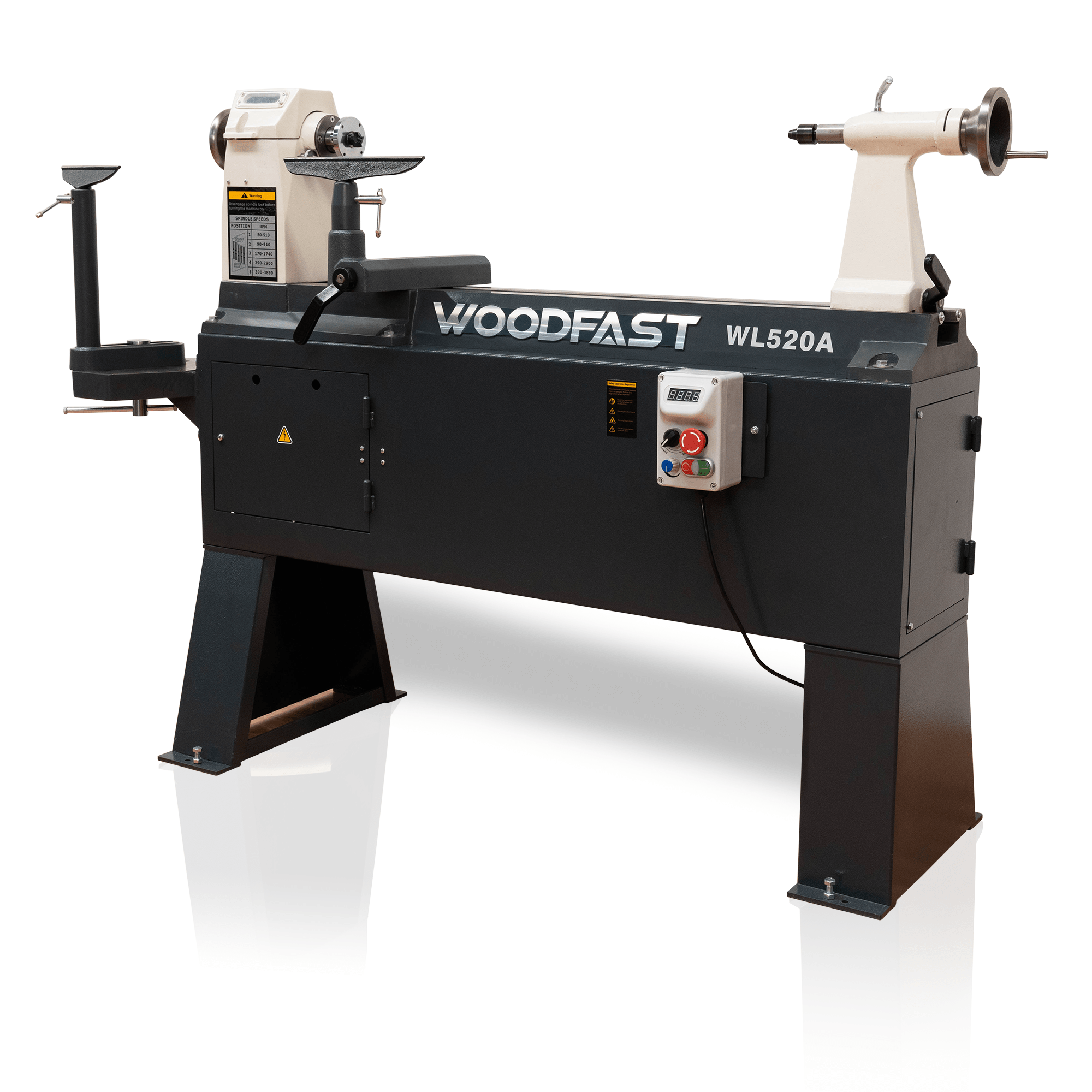

Shop Woodfast

Shop Woodworking