Description

High Quality Veneer Edging for application directly onto wooden substrates such as particleboard, MDF (fibreboard) and plywood - Suitable for Hot Melt Edgebanders or Manual Edgebanding using Virutex AG98R or Iron or other traditional means. We have the largest range of stocked Edging in Australia supplied by quality manufacturers. We offer Edging Solutions for all users (DIY, Hobbyists, Micro Trade Users through to High Industrial Cabinetry / Furniture makers). We offer Cutting and Pre-Gluing facilities for all of our edging in addition to all the stocked lines - please refer to our Edging Services for more details.

Please note we have a larger range of Veneer Products in 0.4mm and 2mm Thickness and larger Roll Sizes.

Suggested Applications:-

- Shelving

- Stereo speaker boxes

- Hobby craft

- Cabinets & cupboard doors

- Renovation of old furniture

How it works:- Iron-on Timber Veneer Edging is coated on the back with a special hot melt adhesive. With heat from an ordinary domestic iron, the adhesive is melted to form a bond with the surface of the substrate.

- Substrate Surface Remove laminate or paint using coarse sandpaper and/or paint stripper. Clean-up substrate surface using stiff-bristled brush.

- Iron-on Timber Veneer Edging Measure and cut edging allowing 10mm overlap on each end.

- Domestic Iron Turn off steam function. Set iron to high heat (cotton setting).

- Position Edging Lay edging over substrate allowing equal overlap on all sides for trimming.

- Cover Edging (not vital) Cover edging strip with brown or grease proof paper to protect surface of edging from excessive direct heat from iron. (see illustration A)

- Iron-on Use on hand to guide and keep edging in position. Starting at one end, iron back and forth. Slowly continue forwards. (see illustration A)

-

Follow-up Pressure Rub wooden block or push roller back and forth immediately after ironing (whilst edging and adhesive still warm) to keep edging in contact with substrate surface as adhesive cools. (see illustration B)

- Note - If result is not acceptable, re-work by repeating steps 3 and 4.

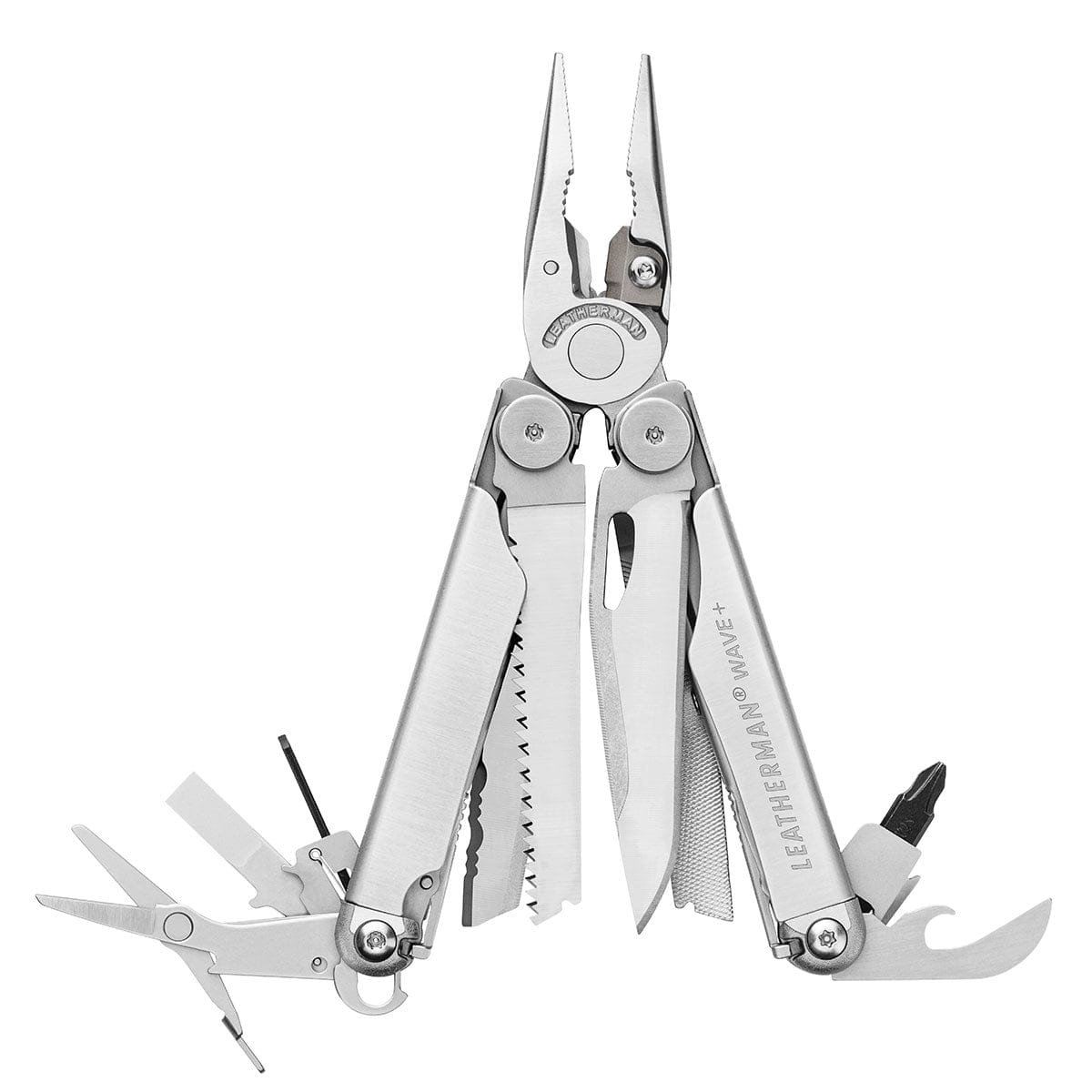

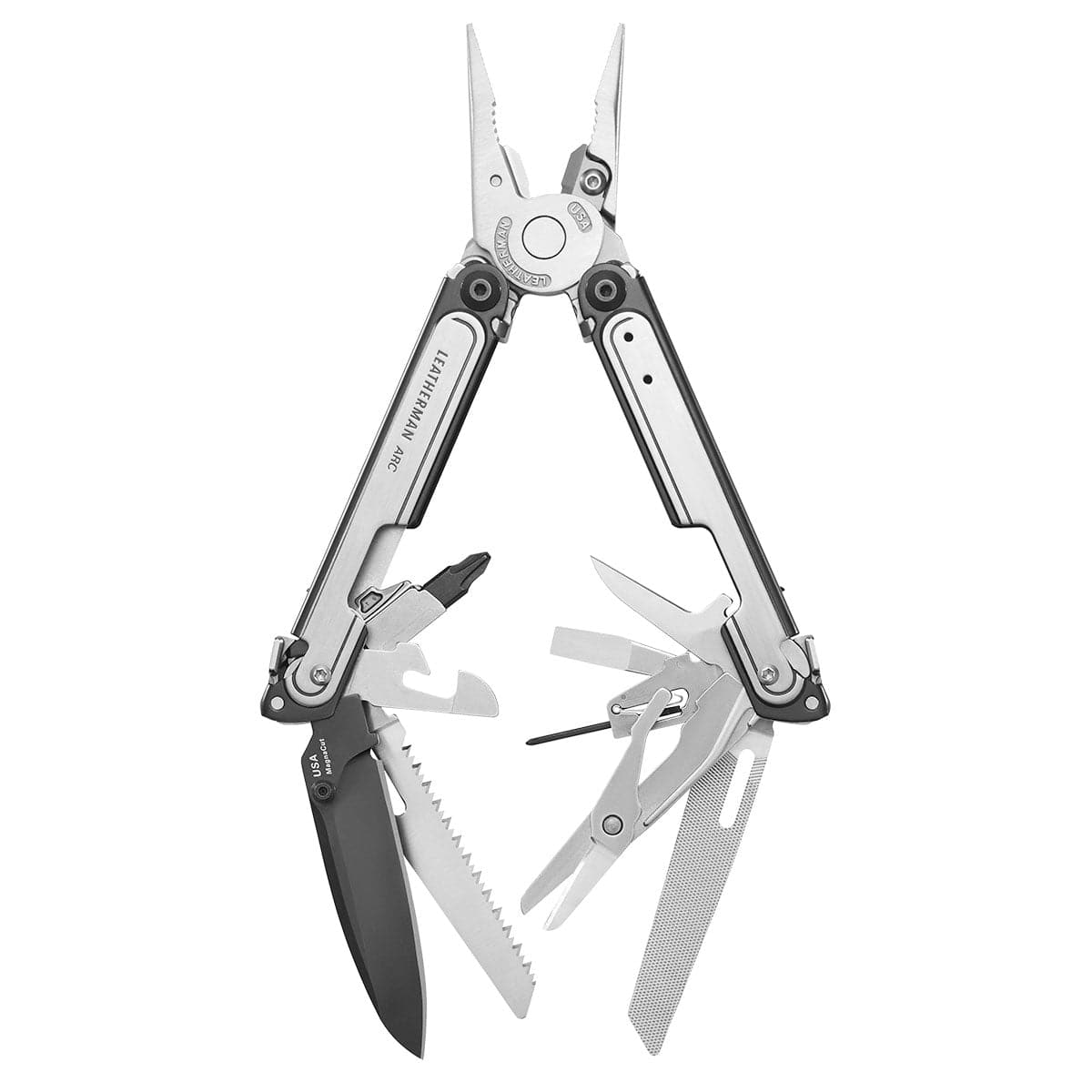

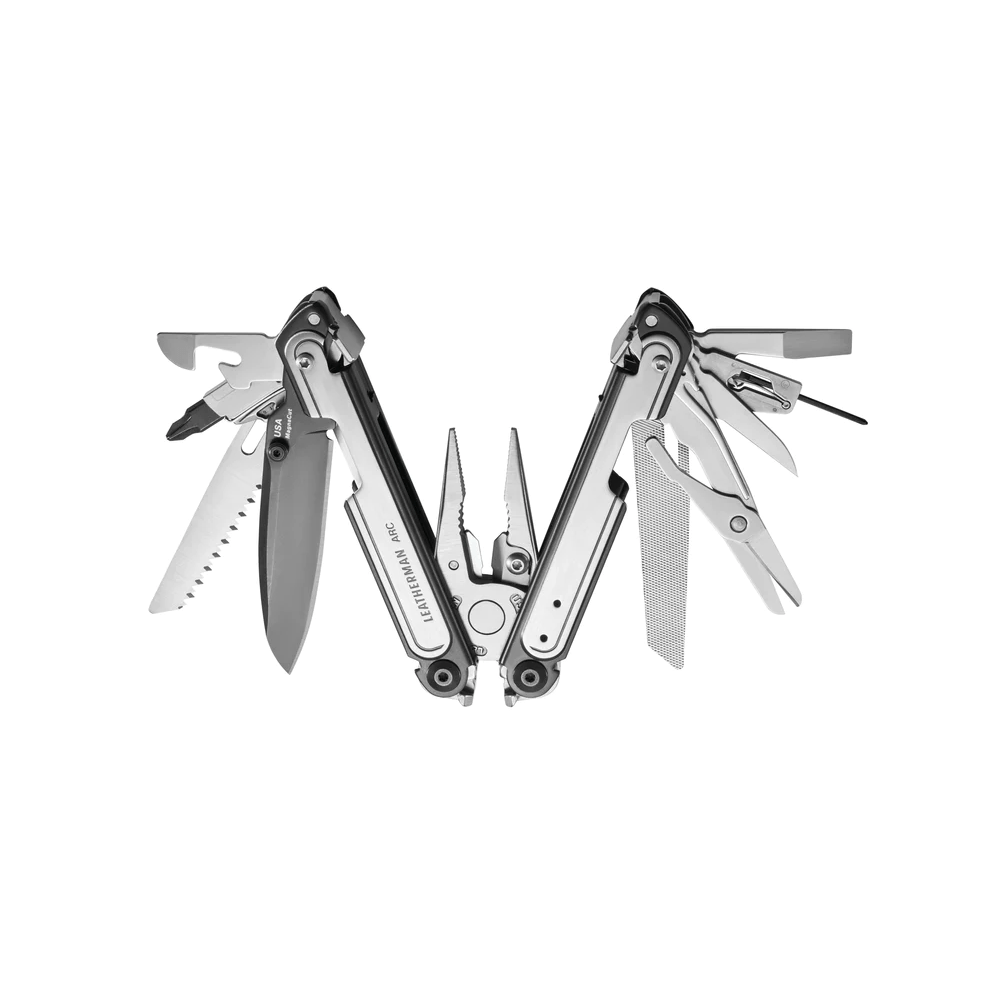

- Trimming Ideally use a router. Alternatively: With fine file - Move file at close angle (15 º) to surface of board. With chisel or utility knife - Work along surface of substrate. Trim carefully to avoid damaging surface of substrate. In all cases, work away from edging towards surface of substrate to stop edging pulling away.

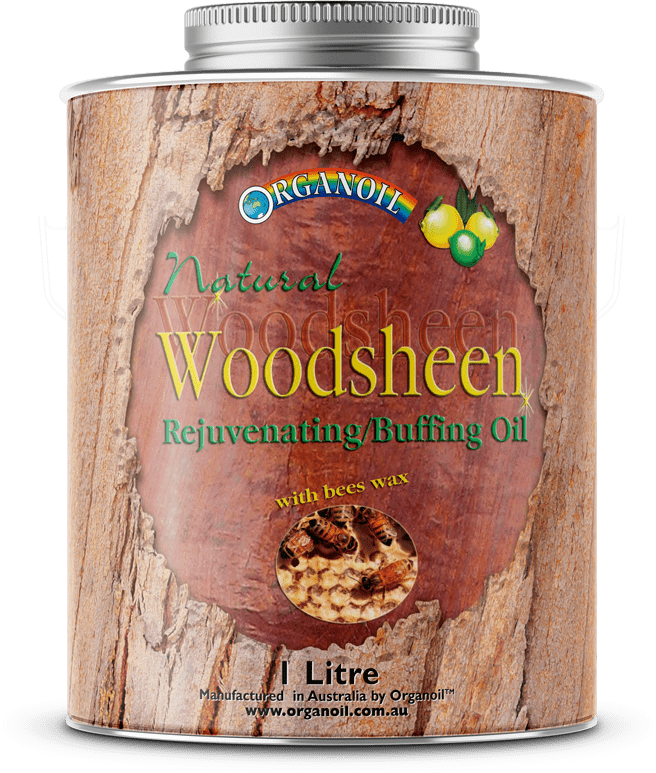

- Finishing If required, fine sandpaper trimmed edges to smooth finish. If desired, Iron-on Timber Veneer Edging can be stained. Apply any standard timber finish.

Additional Information

What's Included

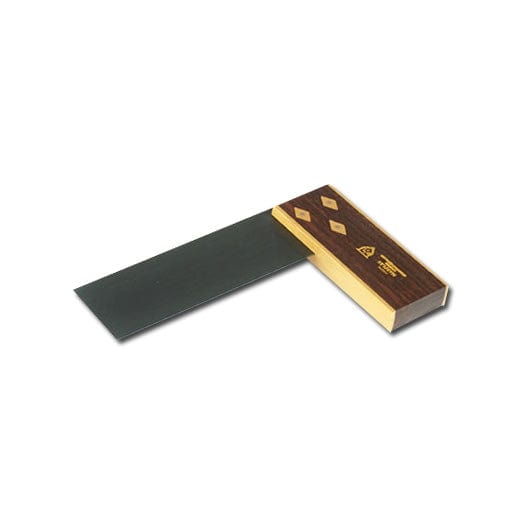

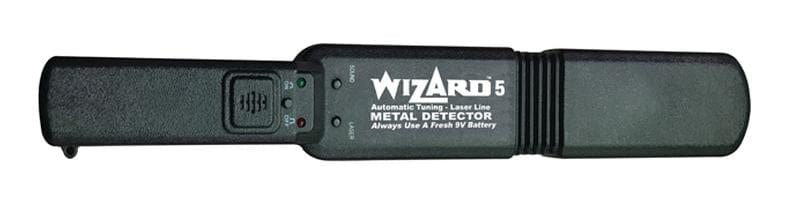

Optional Accessories

Spare Parts

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

hidden

You may also like

Shop All Sale

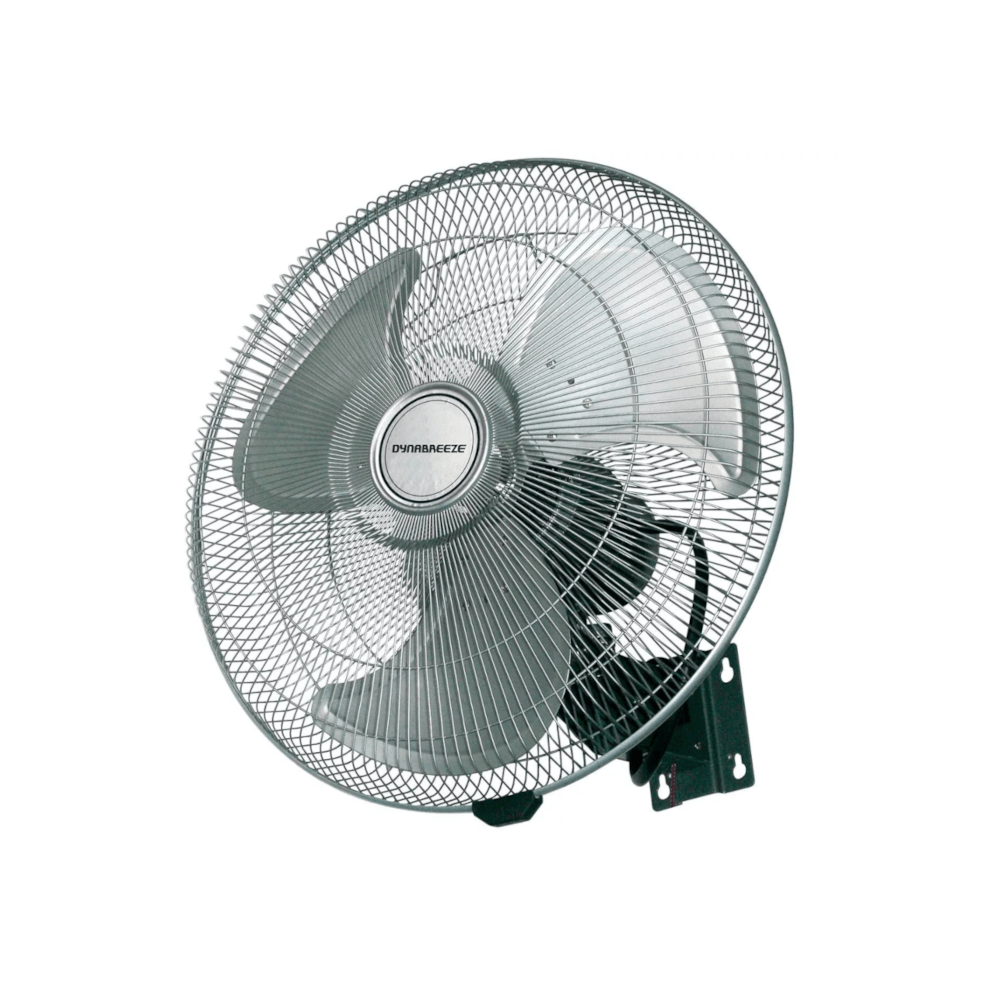

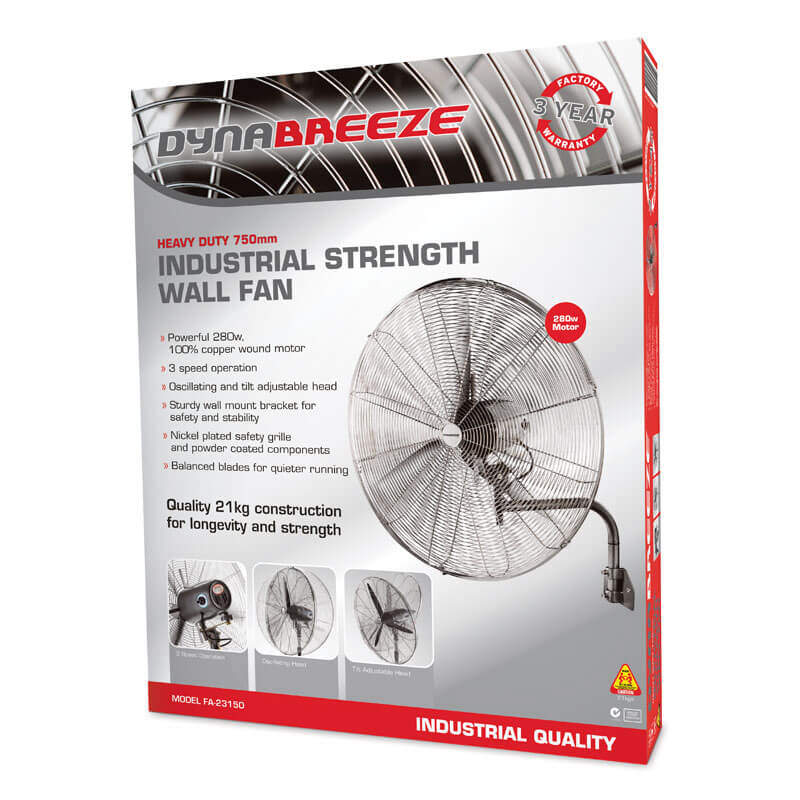

Summer Essentials

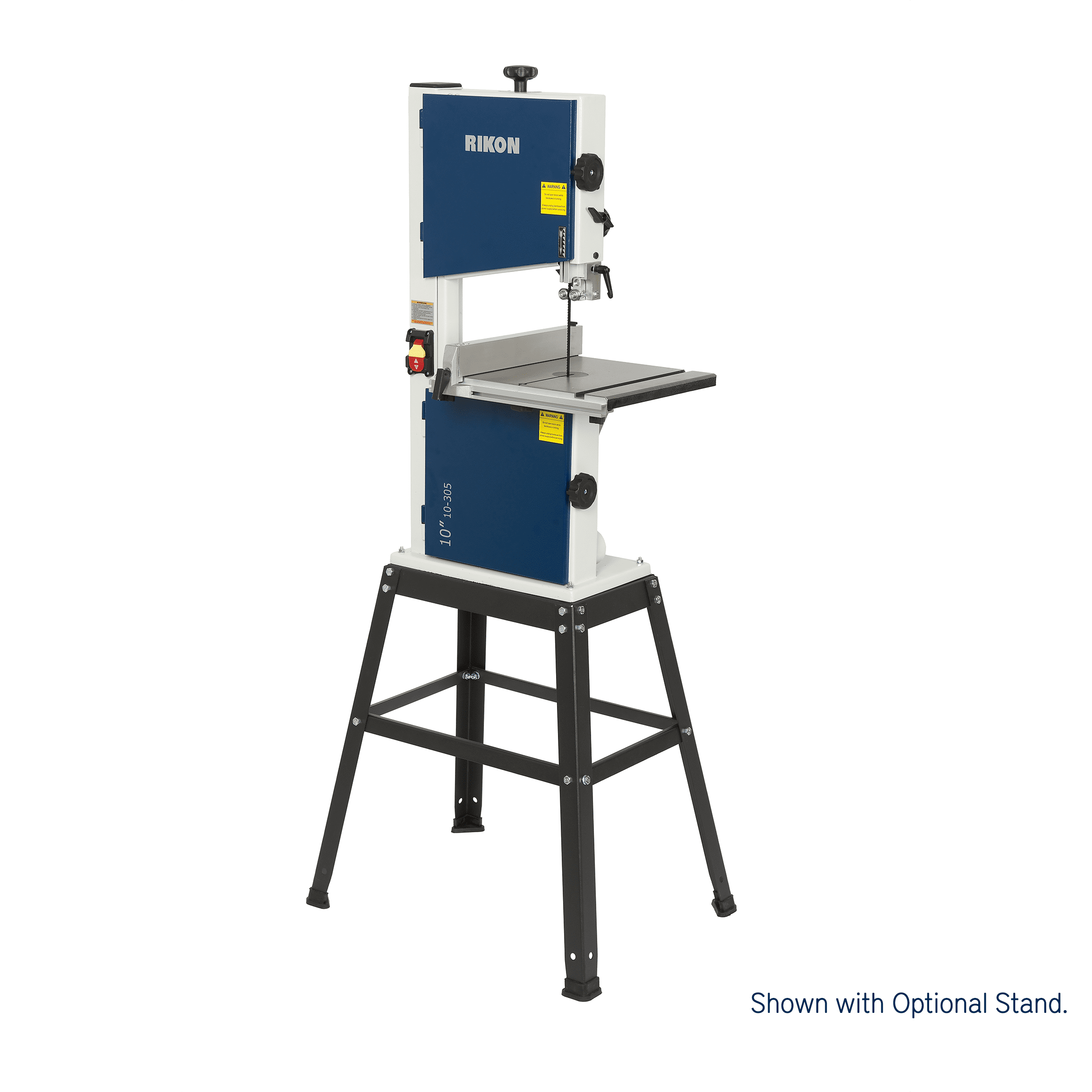

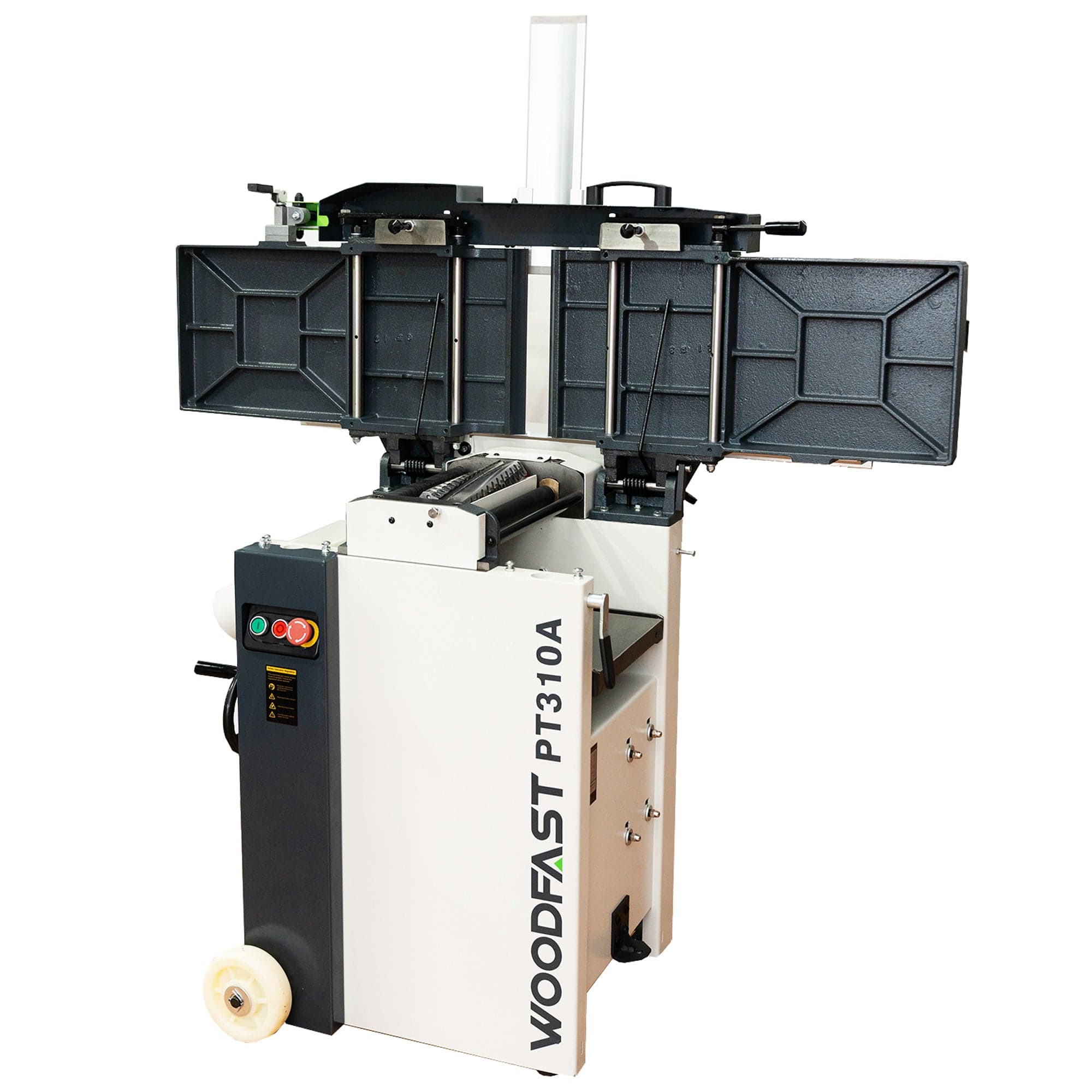

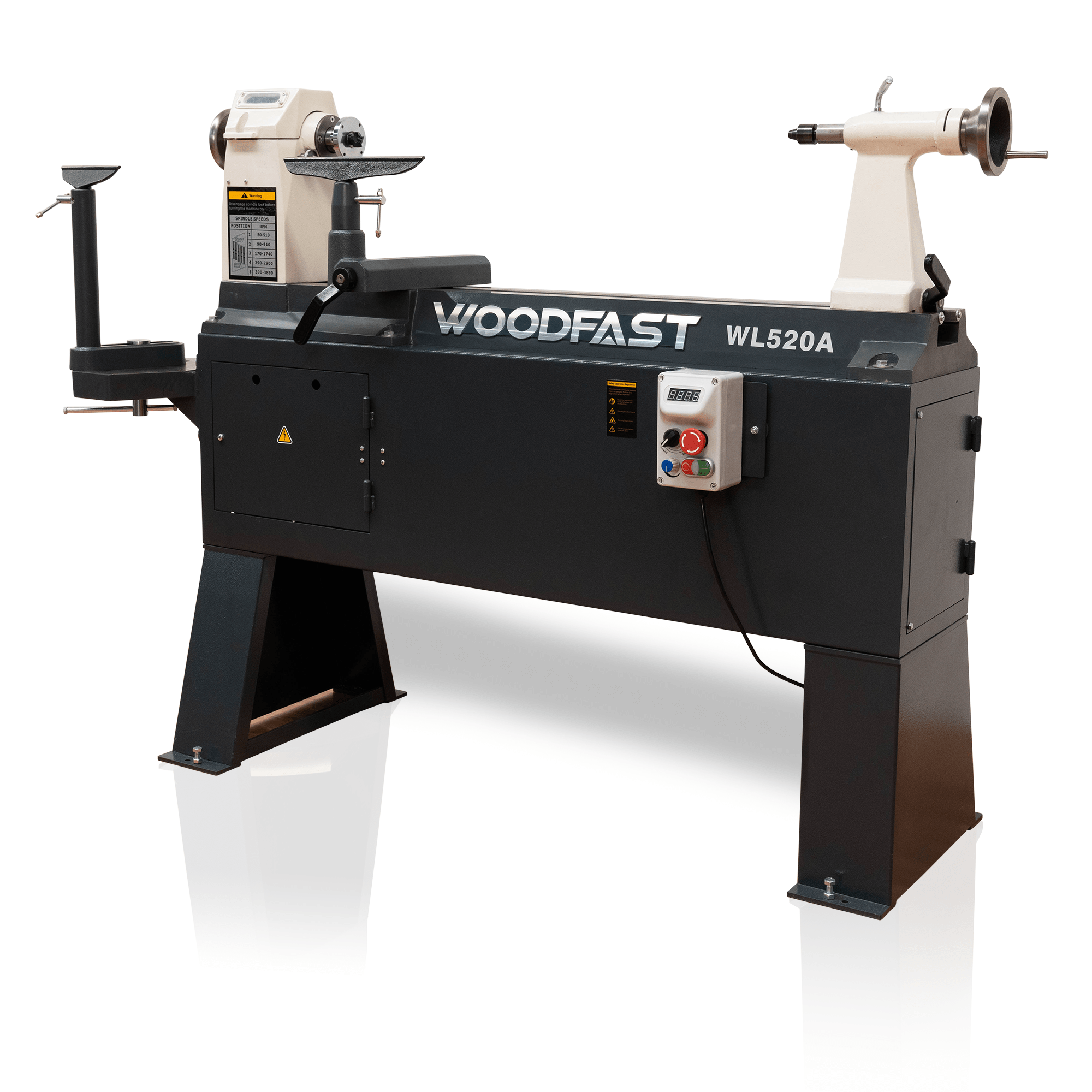

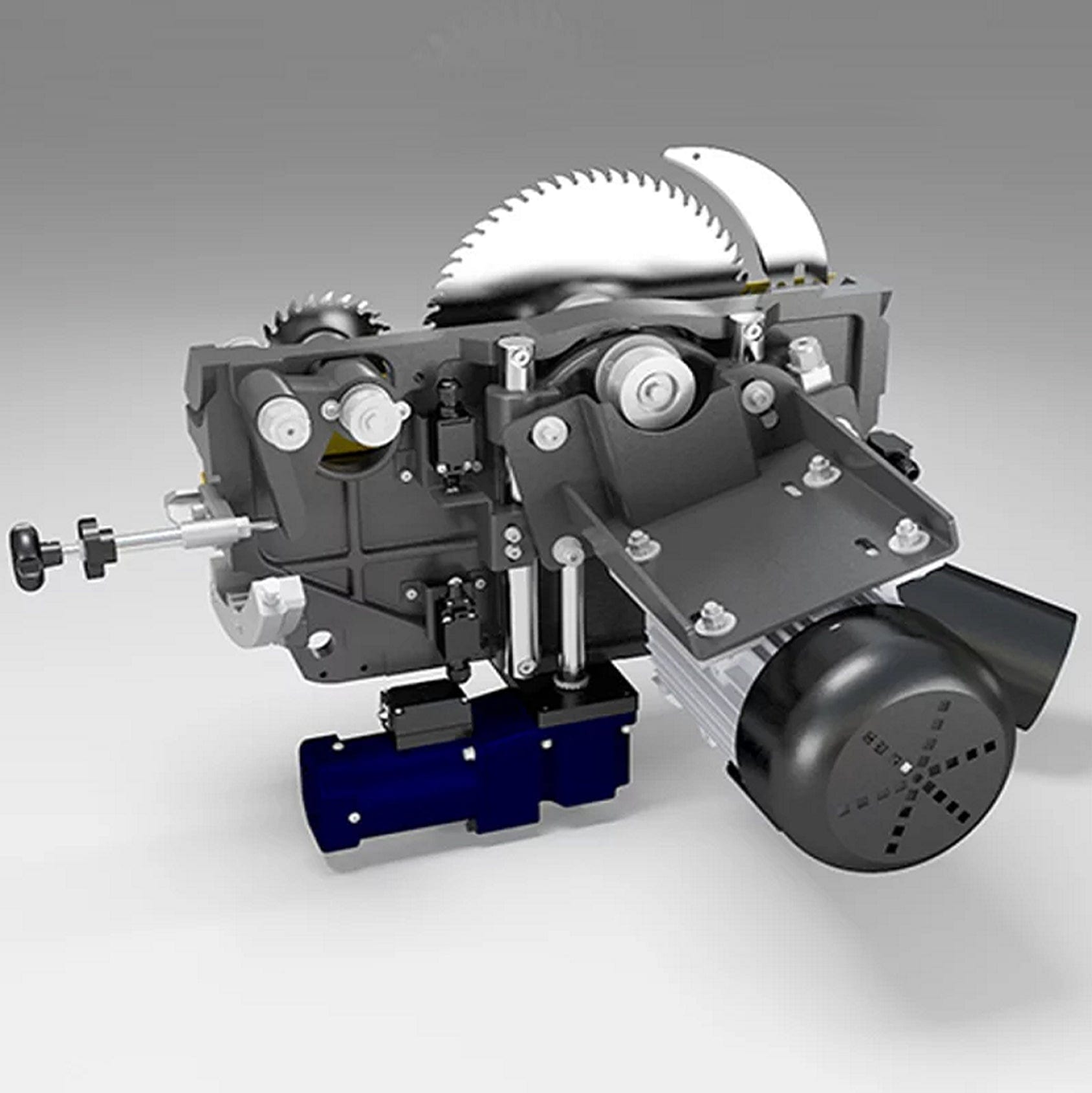

Shop Woodfast

Shop Woodworking